Recently, at the 2024 International Hydrogen Energy Industry Development Forum, China State Shipbuilding Corporation’s (CSSC) Marine Design & Research Institute of China (MARIC) unveiled the design of 2 types of liquefied hydrogen carriers(LH carrier), which triggered strong attention from the participants.

The 180,000 m3 and 20,000 m3 LH carriers released this time have been completed the basic scheme demonstration and jointly certified by American Bureau of Shipping (ABS), among which the 20,000 m3 LH carriers have been granted ABS Approval-in-Principle (AiP).

Hydrogen is non-toxic and does not produce greenhouse gases or pollutants when burned, so as environmental constraints continue to grow, the global demand for hydrogen energy will increase significantly. However, the cost of hydrogen production varies widely across countries and regions, making large-scale cross-border transportation of hydrogen an urgent technology. Therefore, efficient and high-purity liquid hydrogen carriers are an important option for large-scale cross-border transportation over long distances in the future.

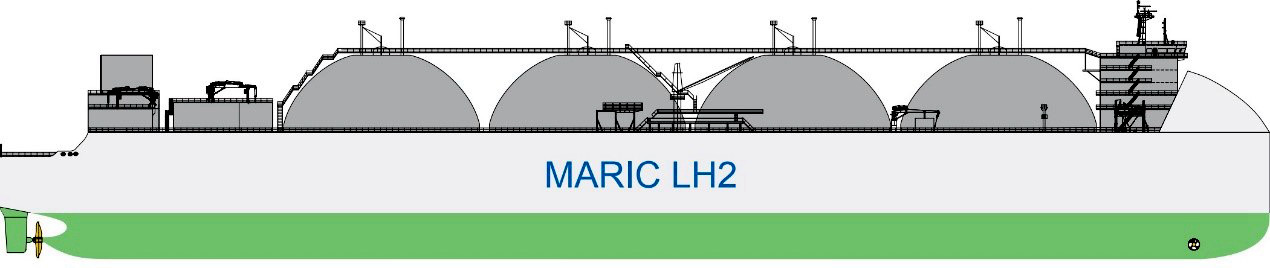

To respond to the demand for large-scale cross-border transportation of hydrogen energy, the 180,000 m3 LH carrier unveiled by MARIC is currently the world’s largest LH carrier in terms of cabin capacity. With an overall length of about 315 meters and a beam of 54 meters, the LH carrier adopts a V-shaped hull with a design draft of 10 meters and a ballast draft of not less than 9 meters. The LH carrier adopts a double-layer spherical tank solution with the smallest surface area-to-volume ratio in order to minimize heat exchange. The evaporation rate does not exceed 0.1% and the volume of a single spherical tank is 45,000 m3.

180,000 m3 LH carrier

180,000 m3 LH carrier

With a design speed of 18 knots, the LH carrier is planned to be propelled by diesel fuel. The main fuel is marie gas oil (MGO), and liquefied natural gas (LNG) can also be selected as fuel for propulsion upon request. The LH carrier is equipped with a proton exchange membrane fuel cell in the nacelle, and the evaporated hydrogen is used for fuel cell power generation. To meet the requirement of line of sight, the living building of this LH carrier is located at the bow, and the windshield is installed at the bow to reduce the sailing wind resistance and to minimize the impact of the banging up waves on the living area in the severe working condition.

The 20,000 m3 LH carrier unveiled this time has an overall length of about 160 meters, a beam of 26.4 meters and a design draft of 6.5 meters. The LH carrier is equipped with a double-layer vacuum single cylinder C-tank, with vacuum and insulation filling between the two layers for an evaporation rate of not more than 0.2%. It is designed for diesel propulsion with a design speed of 14 knots, the main fuel is MGO and the fuel tanks are placed amidships. It can also be propelled by LNG fuel on demand and is also equipped with Proton Exchange Membrane (PEM) fuel cells. In addition, it is optimized for re-liquefaction equipment, compressor layout and GCU layout.

20,000 m3 LH carrier

20,000 m3 LH carrier