- Adopted by the Ministry of the Environment’s ‘Carbon Neutral Technology Research and Development Program.’

- Solves the three major challenges of the domestic shipping industry: ‘decarbonization, crew shortage, and safe navigation’,

- achieving cost competitiveness through standardization.

Achieves zero CO2 emissions not only during operation but also within ports and while docked.

Imoto Lines and Marindows, as a first step in transforming the future of domestic maritime shipping, will build the next generation of zero-emission domestic container ships capable of hybrid operation using Japan’s first exchangeable container batteries, alongside onboard batteries, and generators, and conduct demonstration experiments on the Kobe ~ Hiroshima service.

This project is a challenge towards a sustainable future for domestic maritime shipping, aimed at fundamentally solving the three major challenges the industry faces: decarbonization, crew shortage, and safe navigation. The Ministry of the Environment, Government of Japan recognized its value and adopted it as a three-year project for the ‘FY2024 Carbon Neutral Technology Research and Development Program’.

Achieve ‘complete zero-emission’ CO2 output over the entire lifecycle from fuel mining and manufacturing to usage, not just during operation. For shippers operating globally, reducing CO2 emissions in the supply chain is directly linked to international competitiveness, but the use of renewable energy in ships is just beginning to be developed. This ship will achieve complete zero-emission from fuel mining and manufacturing to usage, by being propelled by renewable energy charged in container batteries.

Fundamental resolution to the industry’s biggest issue–crew shortage. The domestic shipping industry needs a fundamental solution to the dual shortage of crew numbers and skills. This ship will achieve safe and efficient navigation with fewer people and less skill/experience required through electrification, thorough standardization and modularization, and land-based support assuming standardization.

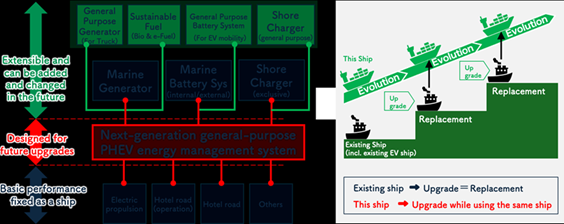

Cost reduction and value enhancement of next-generation advanced vessels. Next-generation advanced vessels currently under development and introduction are not only expensive but also technologically nascent, carrying the risk of future technology obsolescence (devaluation of vessel value).

This ship will significantly reduce operating costs through thorough standardization, modularization, and mass production, aiming to achieve total operating costs, including construction, that are approximately 30% higher than existing ships, but comparable when overall costs are considered.

It also adopts a design that can be flexibly upgraded with the introduction of new technologies and systems, minimizing the risk of technology obsolescence = ship obsolescence.