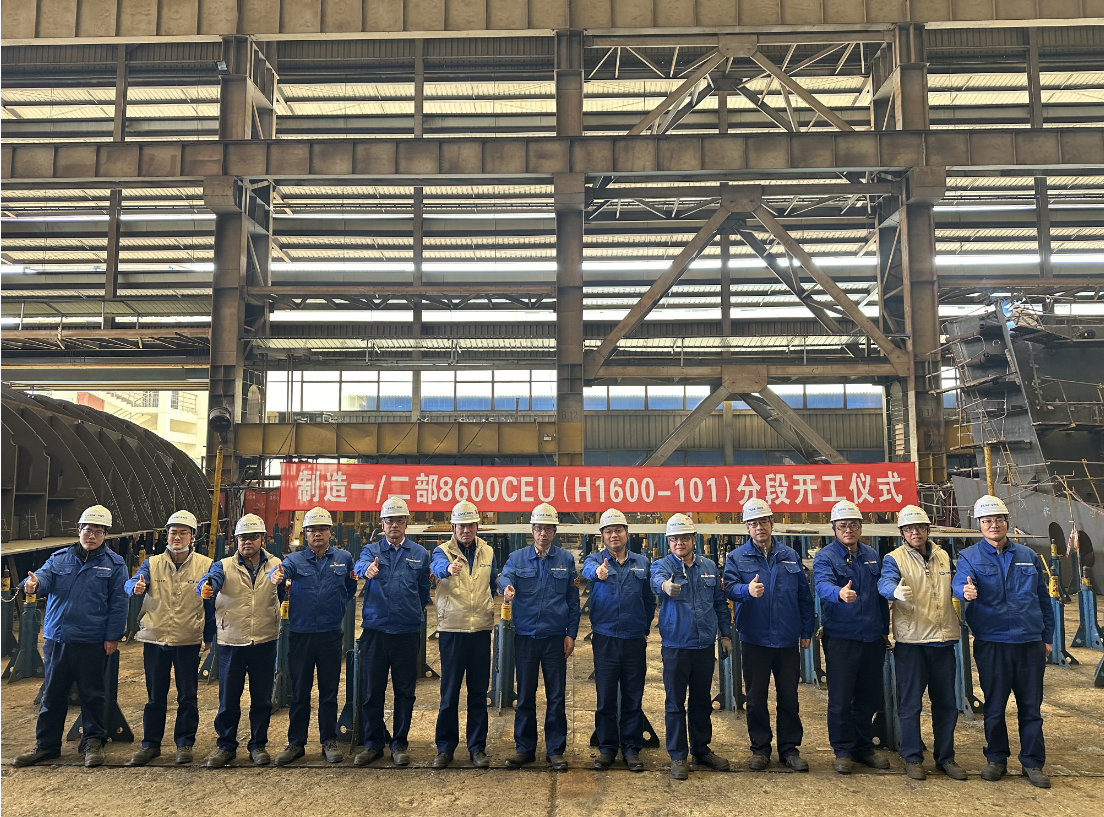

Recently, Shanghai Waigaoqiao Shipbuilding Co., Ltd, (SWS) a subsidiary of China State Shipbuilding Corporation (CSSC), officially started the construction of 8600 ceu liquefied natural gas (LNG) dual-fuel powered pure car and track carrier (PCTC) segment for CITIC Financial Leasing Co. It is the first segment of the first PCTC built by SWS, marking the opening of a new stage of continuous construction of PCTC segments by the Company.

For the first new ship type of PCTC, SWS relies on the experience of large cruise ship segment construction, combines its own production facilities, production sites and other characteristics, accurately organizes the pre-production technology preparation and production planning, establishes and improves the complete project management system and production organization framework, prepares detailed engineering plans, and comprehensively implements the work of JSA and construction process delivery, to achieve the goal of safe and efficient continuous construction, Efficient, metronomic and continuous construction.

Independently developed and designed by hanghai Ship Research and Design Institute (SDARI) under China State Shipbuilding Corporation (CSSC), the PCTC measures 199.9 meters in length overall, 38 meters in breadth, 14.8 meters in depth, 9.2 meters in design draft, with a design speed of 19 knots, and it is classified by DNV and CCS.

Boosted with 14 car decks, the PCTC is fully optimized for each deck in terms of clear height, ramp position, ramp width, strut position, strut spacing, transom side door arrangement, as well as equipment for ventilation, fire fighting, lashing and monitoring.

It is capable of efficiently loading and unloading small cars, wagons, buses, trucks, trailers, as well as ultra-high and ultra-heavy ro-ro cargoes, etc. Also, it is capable of loading various new energy vehicles such as electric vehicles, hydrogen fuel cell vehicles, natural gas vehicles, etc., and is suitable for loading a variety of packaged dangerous goods and containers.

In terms of hydrodynamic performance, the PCTC adopts an integrated strategy, integrates the selection of energy-saving devices, carries out hull line optimization through systematic means, and selects the best line, propeller and energy-saving device combinations in line with the actual operating conditions after continuous parameterization iteration, so that the final propulsion performance is better.

The greenhouse gas emissions of the PCTC are significantly reduced, and the Energy Efficiency Design Index (EEDI) is significantly lower than the Phase III requirements, through the power system adopts LNG dual-fuel low-speed main engine, equipped with high-pressure LNG gas supply system as well as C-type fuel storage tanks and reasonable equipment configuration.

It is especially worth mentioning that it is a upgraded ship type tailor-made for China’s automobile shipping. It is featured with many characteristics such as strong cargo capacity, large loading flexibility, high emission cleanliness, good operational flexibility and good economic efficiency.

Up to now, SWS holds 16 PCTCs for 8600 ceu, 9000 ceu and 10800 ceu, forming a batch construction pattern.