MacGregor’s new gravity self-unloading system eases the discharge of coarse materials from cargo holds, allowing bulk carriers to transport a wider variety of materials in greater volume.

The gravity self-unloading system is a time-tested means of discharging cargo from bulk carriers, with sloping cargo-hold walls designed to facilitate material flow. While a low slope angle is sufficient for unloading free-flowing material such as dry sand, a higher angle is required to effectively discharge coarser material like wood chips – at the expense of reduced storage space. Since the slope angle is decided at the vessel design phase, bulk carriers are typically limited to transporting one type of cargo.

Drawing on decades of experience in self-unloader design and materials research, MacGregor, part of Cargotec, has pioneered a new system that will allow bulk-carrier operators to overcome this limitation and unlock new opportunities.

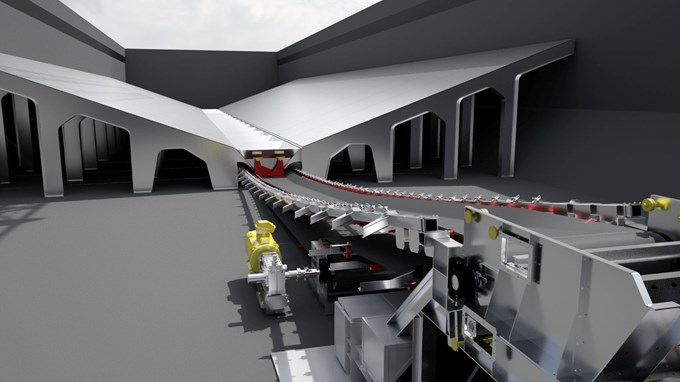

The augmented system, ‘MacGregor GravityVibeTM’, features a patent-pending vibrating unloader that reduces internal friction to ease the discharge of coarse material. While the automated unloading sequence remains a gravity-based operation, GravityVibeTM deploys the vibrating panels as needed to shift any remnants or break the ‘bridges’ that form when cohesive cargo binds together to block the outlet. As a result, the system effectively discharges cargo using a slope angle of just 15–20 degrees – far lower than the 35–60-degree angle required in a conventional gravity self-unloading configuration.

Bulk carriers equipped with GravityVibeTM will therefore be able to handle not only a wider variety of materials but also a greater overall volume of cargo. This will consequently increase earning potential for the operator while reducing carbon dioxide emissions per carried cargo tonne to support compliance with environmental regulations.

“Bulk carrier cargo holds are typically designed to handle a specific kind of material, meaning the ship owner is somewhat limited in the type of assignments they can take on,” commented Mikael Hägglund, Sales Manager, General Cargo Cranes, Transloading and Self unloaders, MacGregor. “MacGregor GravityVibeTM overcomes these limitations to afford owners greater flexibility when taking on new contracts, but it also boosts earning potential and environmental performance by optimising cargo capacity.”

Whereas conventional self-unloaders feature two longitudinal and two transfer conveyors, GravityVibeTM’s low slope angles mean that it functions with just one longitudinal conveyor. With fewer components, the system is less complex, which means its maintenance and spare-parts requirements are reduced, in combination with the increased flexibility, resulting in improved cost efficiency. The streamlined set-up also minimises spillage and the need for cleaning, with crew benefiting from a lighter workload and improved safety.

Crucially, with another patent-pending component from MacGregor isolating the vibrating panels from the hull structure, GravityVibeTM minimises the transfer of vibrations and noise to other parts of the ship. This helps to protect the vessel and its critical machinery from stress-related damage while ensuring comfortable working conditions for personnel.

“As the culmination of decades of experience in self-unloading systems and years of targeted research, MacGregor GravityVibeTM is our most advanced self-unloader yet,” said Tomas Wallin, Senior Product Owner, Self-Unloaders, MacGregor. “We developed the system according to established best practice, using textbook understanding of material behaviour in combination with a decisive innovation on how to handle cargo types with different properties. We have also tested it in collaboration with leading universities.”

While GravityVibeTM is primarily envisaged as an onboard installation, MacGregor’s studies have shown the technology to be equally applicable to hoppers, where the action of the vibrating panels would minimise the reliance on gravity alone, allowing a lower height and wider inlet. This would in turn make it easier for crane operators to transfer cargo into the hopper for more accurate and efficient operations, while the smaller dimensions would also mean a lower overall investment.

MacGregor is offering customers the opportunity to validate GravityVibeTM’s handling of their chosen materials in full-scale mock-up demonstrations at the company’s test facilities.