MAN Energy Solutions plans to deliver later this year its first-ever engine fuelled by ammonia for installation on a new vessel in Japan and will be ready to offer ammonia-powered engines to its clients after 2027, its chief executive said.

Ammonia is among several alternative fuels that shippers are exploring to reduce emissions. The shipping industry transports around 90% of world trade, but accounts for nearly 3% of the world’s carbon dioxide emissions, and installing engines that burn cleaner fuels on vessels could help slow global warming trends.

The ammonia-fuelled ship will take a year or two to undergo trials, while fuel supply, bunkering infrastructure and safety standards have to be created, MAN Energy Solutions CEO Uwe Lauber told Reuters late on Friday.

“Actual sales (of ammonia engines), I would not foresee it before 2027,” he said.

Further cooperation with port authorities, including in Singapore, the world’s biggest hub for ship refuelling, also known as bunkering, is required to ensure ammonia bunkering is carried out safely, Lauber said.

While ammonia doesn’t contain carbon, it is toxic and will require stringent safety measures when being handled as a ship fuel.

Lauber did caution, however, that the output of green ammonia, which is produced from renewable fuels and the electrolysis of water and is considered a far cleaner fuel source, is unlikely to reach a certain scale before 2030, Lauber said.

“If people believe this will come tomorrow that’s a dream, this will not come. We need to build up infrastructure,” he said.

“A lot of work needs to be done also on safety devices with the classification societies. There are no rules today available on how to design an ammonia system on a ship,” Lauber said.

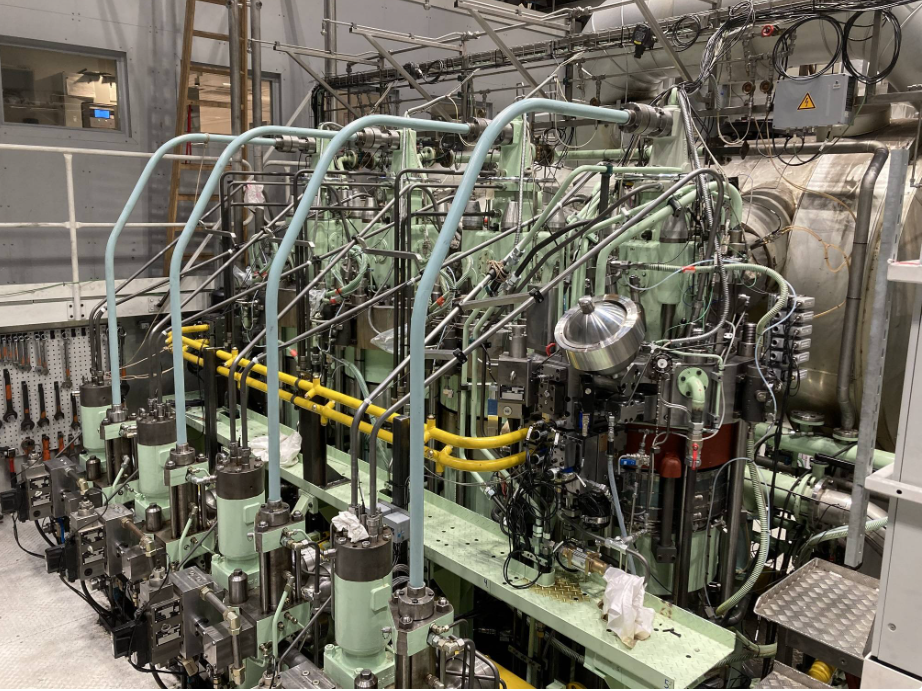

On Friday, MAN Energy Solutions opened a 20 million-euro ($21.6-million) workshop in Singapore, its largest outside Europe, to maintain, repair, and retrofit fleets using its dual-fuelled engines that can burn oil and alternative fuels such as liquefied natural gas and methanol.

The company plans to increase the number of staff in Singapore to 400-500, up from 250 now, and will train clients on how to operate dual-fuel engines more efficiently, Lauber said.

“The biggest burden is to address the existing fleet because our customers do not want to throw away their ships,” he added.

Depending on the ship’s age, value and its engine type, Lauber estimated that 3,000-5,000 of the 20,000 ships globally that use MAN engines can be retrofitted to burn alternative fuels and the conversion package could cost between $25 million to $50 million.

MAN is also conducting tests on its engines to use 100% biofuels, up from 30% currently, he said.

Source: Reuters