On December 5, at Marintec China 2023, Hudong-Zhonghua Shipbuilding (Group) Co., Ltd, a subsidiary of China State Shipbuilding Corporation (CSSC), unveiled 10 types of high-end vessels. Meanwhile, Hudong-Zhonghua Shipbuilding has launched 4 green, low-carbon and high-technology new ship designs, which have been awarded the “Acceptance in Principle” (AIP) by 4 major classification societies.

This is the third batch of new vessels launched by Hudong-Zhonghua Shipbuilding this year. Previously, the company has launched four types of new vessels, including the world’s largest 271,000 m3 LNG vessel. So far, Hudong-Zhonghua Shipbuilding has launched 8 types of new ships in this year, creating the highest record of annual new ship type research and development of the enterprise.

At the exhibition, Hudong-Zhonghua launched a 174,000 m3 LNG vessel equipped with Carbon Capture System (OCCS), contributing Hudong-Zhonghua’s solutions to the development of low-carbon shipping. It is recognized in principle by American Bureau of Shipping (ABS), British Register of Shipping (LR), Det Norske Veritas (DNV) and Bureau Veritas (BV). The ship maintains a series of advantages of the fifth generation LNG ship such as good rapidity, low sailing emissions, high degree of advancement and global versatility, etc.

Also, a domestically produced carbon capture system featuring high absorption rate, low energy consumption, and compact space was designed and installed to meet the 2040 CII emission standards. Developed by Shanghai Marine Diesel Engine Research institute (SMDERI), the system has a capture efficiency of over 90% and CO2 purity of over 99%, and can be customized to meet different operational plans and CII emission requirements.

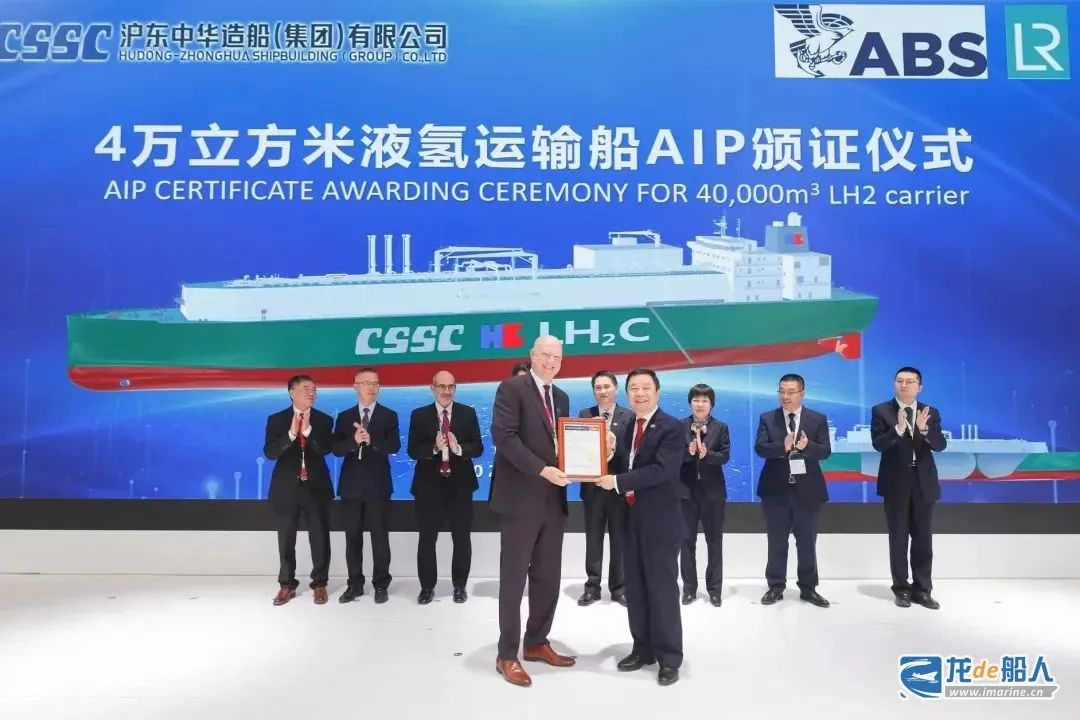

The 40,000 m3 Liquid Hydrogen Carrier has been approved in principle byABS andLR.The 40,000 m3 Liquid Hydrogen Carrier is the first domestic specialized vessel for transporting liquid hydrogen, which is designed by Hudong-Zhonghua Shipbuilding based on the demand of the potential projects in the international market. The ship has an overall length of 210.00 meters, a beam of 32.2 meters, a depth of 20.00 meters, a design draft of 7.0 meters and a design speed of 15 knots.

The ship is equipped with 3 liquid cargo tanks, adopting double-layer vacuum insulated IMO C-tank liquid cargo enclosure system, low-temperature liquid phase piping system adopting vacuum insulated double-wall pipe, adopting dual-fuel (MDO and hydrogen) electric propulsion system, and realizing zero-carbon emission in gas mode.

The 88,000 cubic meters liquid ammonia carrier has been approved in principle by ABS and LR. The vessel is the largest liquid ammonia carrier based on 32.25 meters beam, with an overall length of 230 meters, a beam of 32.25 meters and a depth of 24 meters. The ship adopts A-type liquid cargo tanks with a capacity of 88,000 m3, a speed of more than 16 knots and a range of 12,000 nautical miles.

The ship’s power system adopts fuel oil/liquid ammonia dual-fuel low-speed engine and generator, both of which are equipped with SCR device, which can meet IMO TIER III requirements in both fuel oil and ammonia fuel modes, and can effectively prevent ammonia from escaping. In order to ensure that the crew is not harmed by toxic ammonia during operation, the ammonia fuel leakage detection, piping and supply system, and water spray absorption system are all specially designed to collect escaped ammonia even in the event of a total loss of power.

The 16000TEU ammonia-powered container ship has been approved in principle by DNV and BV. The vessel has an overall length of 367m, a beam of 51m and a depth of 29.9m, and adopts a B-type ammonia-fueled stand-alone tank with a capacity of about 14,000m3.

Compatible with MAN and WnGD large bore low speed engine, fully reduce energy consumption, can be matched with ALS system to further improve economy. Adopting ammonia-fueled main engine solution and equipped with SCR, the vessel meets Tier llI requirements and realizes zero carbon emission. Equipped with pressure accumulator water spray absorption system, it can realize fugitive ammonia recovery and storage under any working condition including power failure of the whole ship.

Therefore, the vessel is characterized by light weight structure, high cargo carrying capacity, excellent overall performance, as well as being green, safe and reliable, thus providing a highly competitive new option for the shipping industry.