On December 5, at the Marintec China, Jiangnan Shipbuilding released a number of ship type certifications and signed a joint research and development agreement on unmanned ships, marking that the road of Jiangnan Shipbuilding’s high-quality development and product structure transformation is getting farther and farther.

On that day, Jiangnan Shipbuilding released the world’s first and the world’s largest 24,000 TEU nuclear-powered container ship model, marking the company’s revolutionary achievements in the field of research and development of “net-zero emission” ship type, and further expanding the company’s container ship series brand.

At the ceremony, Det Norske Veritas (DNV) presented the company with a certificate of approval in principle for this type of vessel.

This type of vessel adopts the internationally advanced Generation IV reactor type molten salt reactor solution. With high safety, high temperature and low pressure operation of the reactor, the ship can avoid the core melting in principle, and has the characteristics of non-proliferation and inherent safety. This ship type adopts disordered high-pressure resistant vessel and pipeline, which can be quickly solidified under ambient temperature even if a breach accident occurs. And the molten salt can be discharged out of the heap in addition to the normal means of stopping the heap after the accident, so as to realize rapid stopping of the heap and preventing the expansion of the accident.

Meanwhile, the power unit of this ship type is arranged in a safe position on board. The power system adopts double-side redundancy design to fully ensure the safety of the power supply system and has the function of emergency evacuation from the personnel gathering area.

Features of “KUN-24AP”:

Intrinsic Security:The main scale of this ship type is suitable for the ship owner’s operation, and the power system arrangement is more compact compared to the traditional ship, which can provide more spaces. The traditional chimney cabin shed has been canceled, and the first room cabin scheme has been adopted, with the nuclear power cabin located amidships, which not only increases the number of spaces, but also improves the comfort and safety.

Net Zero Emission: This ship type adopts all-electric program for the whole ship, and the propulsion system adopts double motors, double shafts and oars and double rudders, with large installed power, high speed and good maneuverability. Compared with various alternative energy solutions, this ship type can realize shorter ship length and more box spaces, and the space utilization rate and energy utilization rate have been improved.

Economic comparability:The vessel adopts a convenient and quick replacement program, replacing the “battery” every 15-20 years, without worrying about fluctuations in the price of green fuel and refueling issues.

On the same day, Jiangnan Shipbuilding released the 200,000 m3 NH3-FRSU vessel type. Lloyd’s Register (LR) issued a Certificate of Recognition in Principle to the company for this ship type.

The 200,000 m3 super-large liquid ammonia carrier is a future ship type independently developed by Jiangnan Shipbuilding, equipped with regasification module. This type of ship solves the problem of large-scale liquid ammonia transportation while using liquid ammonia as ship power fuel, making it a zero-carbon and environmentally friendly ship in the true sense of the word. It can be heated and re-gasified onshore as required, transported to onshore pipelines and provide a stable input for onshore power generation. Compared with onshore facilities, this type of vessel not only has a short construction time, but also has a great cost advantage.

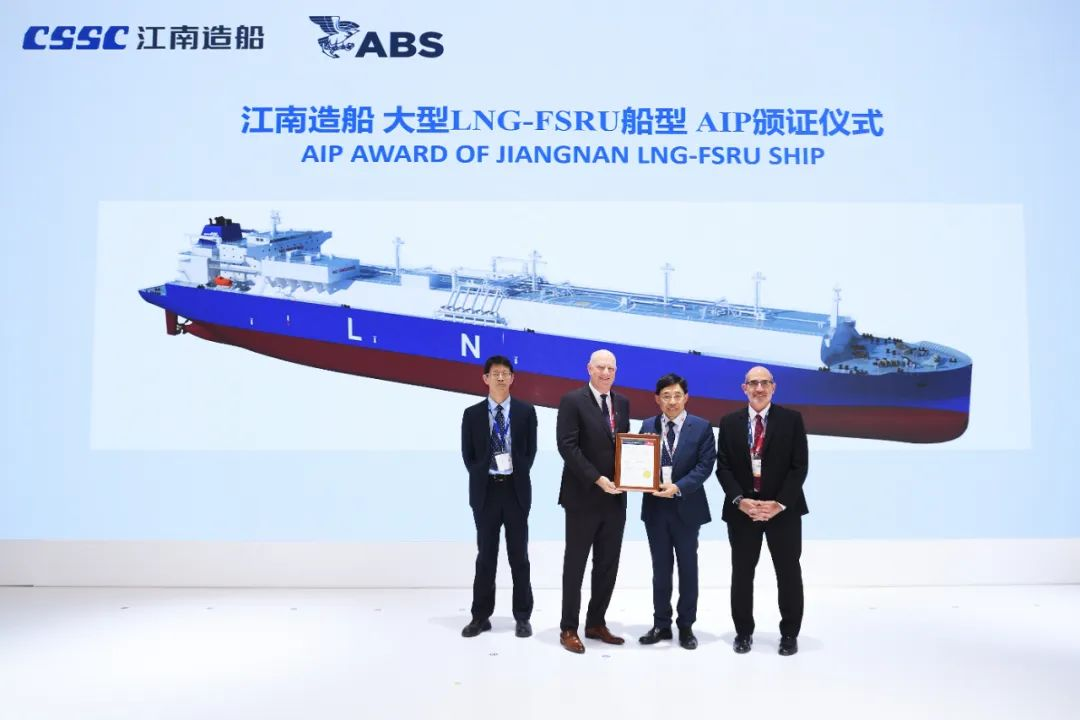

Also, Jiangnan Shipbuilding released a 175,000 m³ LNG-FSRU vessel type. The American Bureau of Shipping (ABS) issued the company with a Certificate of Approval in Principle for the vessel type.

LNG-FSRU is a special equipment integrating various functions such as LNG reception, storage, transshipment, regasification and export, etc. It is equipped with a power propulsion system and functions as an LNG carrier.

This ship type is independently developed by Jiangnan Shipbuilding for European Baltic terminal energy demand. It can meet the requirements of most LNG loading and unloading ports in the world, and is equipped with 4×250 mmscfd regasification unit.

Jiangnan Shipbuilding’s LNG-FSRU provides shipowners with abundant options in response to the latest technological development trend in the international market, and the program meets the high requirements of class notation such as SMART, SUSTAIN, EEMS, Carbon Capture Ready, etc. Moreover, the company also provides highly flexible and secure regasification heat source solutions, regasification module meets HIPPS SIL 3 level requirements, equipped with regasification metering system, system design meets the new requirements of information security, and mooring cables are equipped with anti-kickback safety design.

With advanced design indexes and rich programs, this vessel type can meet different customer needs and provide diversified solutions for customers.

Besides, Jiangnan Shipbuilding’s ammonia-fueled large container vessels were awarded the Lloyd’s Register (LR) Certificate of Approval in Principle.

The 14000TEU ammonia fuel-powered container ship is another type of high-efficiency, green, environmentally friendly and zero-carbon ultra-large container ship that Jiangnan Shipbuilding has developed independently in the field of the main ship type. And Jiangnan Shipbuilding owns completely independent intellectual property rights.

The shape of the ship adopts approximation techniques and efficient global optimization algorithms, and is closely integrated with numerical pool (CFD) and physical pool (ship model test) validation. In addition, comprehensive hydrodynamic performance optimization is carried out considering the requirements of the ship owner’s operating conditions, thus obtaining a ship model with excellent performance in all aspects and meeting the most stringent emission requirements in the world.

And finally, Jiangnan Shipbuilding and China Classification Society (CCS) signed a joint research and development agreement on global navigation “unmanned” merchant ships for the application of MASS rules.

China Classification Society (CCS) is an important long-term strategic partner of Jiangnan Shipbuilding, and the two sides have successfully cooperated on many projects. The signing of the joint research and development agreement is a move of both sides to deepen cooperation, combine strengths and complement each other’s advantages.