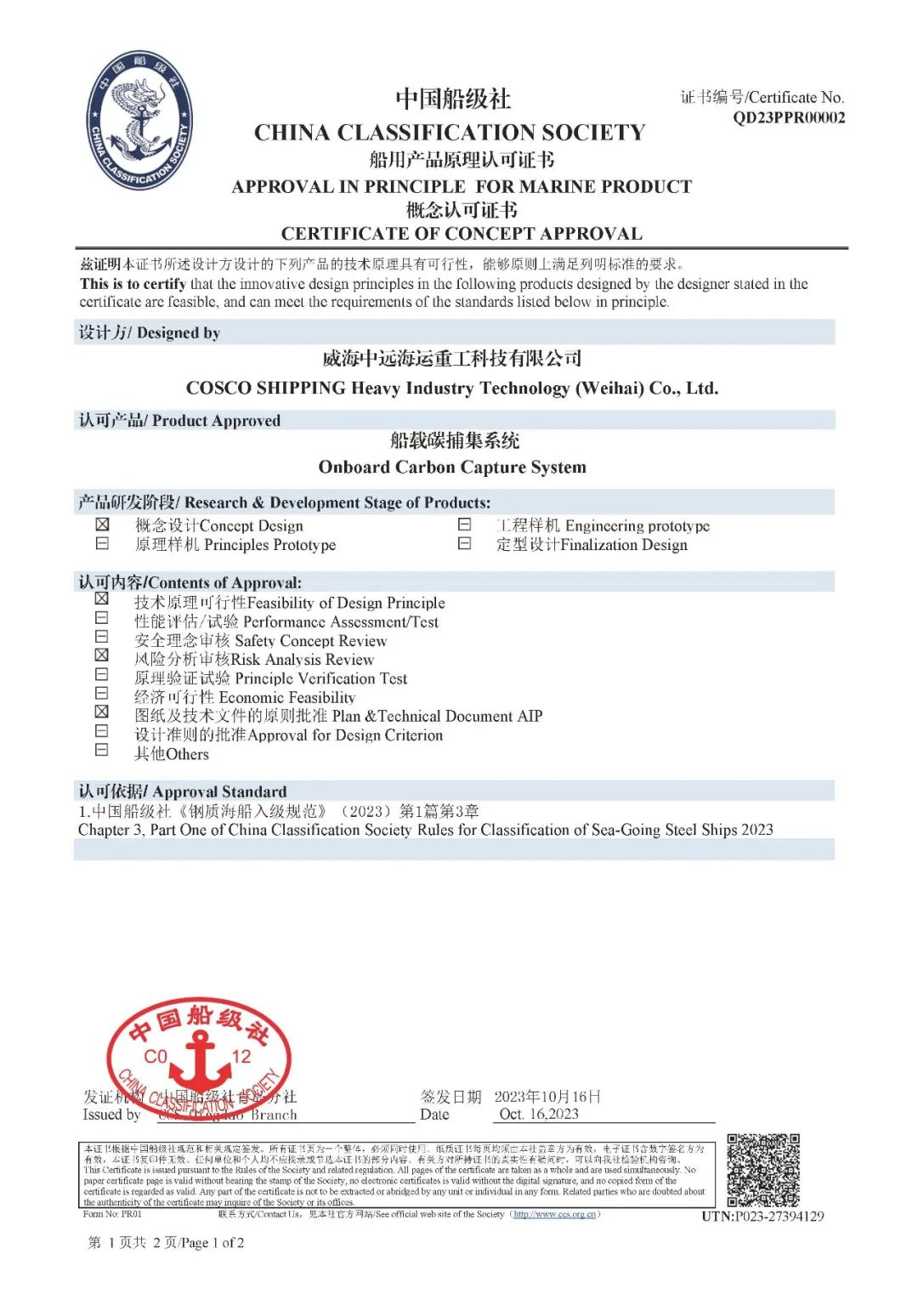

Recently, the shipboard super gravity carbon capture system independently developed by COSCO Shipping Heavy Industry Technology (Weihai) Co., Ltd. has successfully obtained the principle recognition certificate issued by CCS, which is the first set of shipboard carbon capture system based on super gravity technology recognized by CCS in China. The system is characterized by high gas-liquid ratio, small equipment volume, high carbon capture efficiency, low energy consumption and other technical advantages, which provides a green and low-carbon solution for the shipping industry to cope with the domestic and international carbon emission reduction policies with both ship type applicability and short- and medium-term technical advantages.

Shipboard carbon capture system is a kind of shipboard exhaust gas aftertreatment system used to separate and enrich carbon dioxide in ship exhaust gas, which can reduce ship fuel costs and efficiently fulfill the carbon reduction targets at various stages. Currently, the more mature tower carbon capture technology is the main technology in the market. Due to its inefficient gas-liquid mass transfer performance, the tower-based carbon capture system occupies a large space and consumes a high amount of energy, which results in a reduction of ship capacity and a sudden increase in the ship’s electrical and thermal loads. Therefore, there is an urgent need to develop a new type of shipboard carbon capture system with efficient gas-liquid mass transfer performance.

Supergravity technology is a highly efficient process intensification technology, which can intensify gas-liquid mass and heat transfer, reduce the size of the equipment and reduce the space occupied. The supergravity carbon capture system independently developed by COSCO Shipping Heavy Industry Technology (Weihai) combines new supergravity equipment, high-efficiency recycling process for poor and rich liquids and self-developed high-efficiency absorbent, which maintains a high gas-liquid ratio and carbon capture efficiency (≥85%) while effectively improving the operational flexibility and stability of the system, and significantly reduces the absorbent dosage and the energy consumption of the system. Compared with the shipboard tower carbon capture system with the same processing capacity, the comprehensive energy consumption of this carbon capture and storage system has decreased by more than 40%, and the height, weight and volume of the equipment have decreased dramatically, which can effectively provide targeted solutions to the difficulties and pain points of carbon emission reduction for ocean-going vessels.