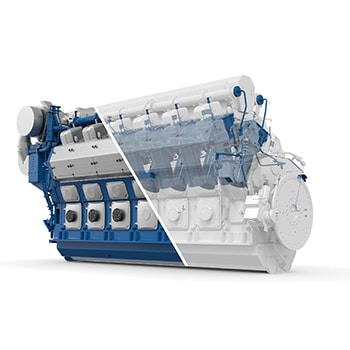

Wärtsilä has introduced a new methane slip reduction solution for its Wärtsilä 50DF dual-fuel engine. The new technology converts Wärtsilä 50DF dual-fuel (DF) engines to spark gas (SG) operation. This enables a more optimized combustion process, improving efficiency and lowering methane emissions.

While operating on LNG, the new spark gas conversion for the 50DF is designed to reduce methane emissions by up to 75% more than the standard 50DF engine.

The new methane slip reduction solution minimizes methane emissions by introducing an electrically controlled pre-combustion chamber valve for a more optimized combustion process. The estimated result is that, on an IMO weighted (E2-cycle) average, the new solution reduces methane emissions down to 1.1% of fuel use.

“The use of LNG and cutting methane emissions is one of the most effective ways to decrease overall greenhouse gas (GHG) emissions from marine engines over the next decade, complementing other efforts to reduce CO2 emissions,” said

Roger Holm, president of Wärtsilä Marine & executive vice president at Wärtsilä Corporation. “As the shipping industry strives for more sustainable operations, this new solution represents an important milestone on the road to advancing lower carbon fleets.”

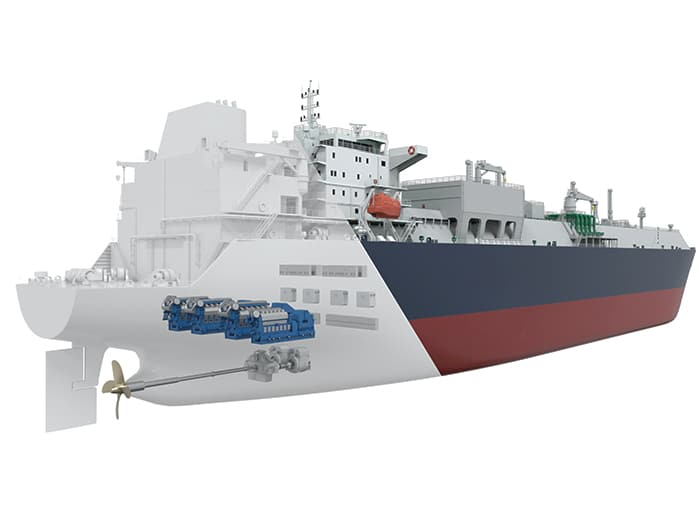

The development of the new methane slip reduction solution was made possible through extensive collaboration between Wärtsilä and Chevron Shipping Company. As previously reported, one engine on each of six Chevron LNG carriers will be converted from DF to SG as part of Chevron’s aim to reducing the carbon intensity of its operations.

The solution is now available to all vessels in the industry with existing Wärtsilä 50DF engines used in diesel-electric propulsion systems, the majority of which are LNG carriers.

The new solution is optimized for LNG as fuel, therefore producing a better energy output per unit of fuel. This means fuel gas savings of up to 4.6 percent, as well as lower methane emissions.

“Wärtsilä has an extensive track-record in reducing methane slip from LNG-fueled engines, not only as newbuild solutions, but also through retrofitting existing installations,” said Holm. “This latest technology complements our extensive portfolio of solutions aimed at reducing methane emissions from vessels.”