On April 7, Nantong CIMC Sinopacific Offshore & Engineering Co.,Ltd. (CIMC SOE) welcomed the simultaneous steel cutting of a 40,000 cubic meter LPG/liquid ammonia carrier and two SPP40 oil platform supply vessels.

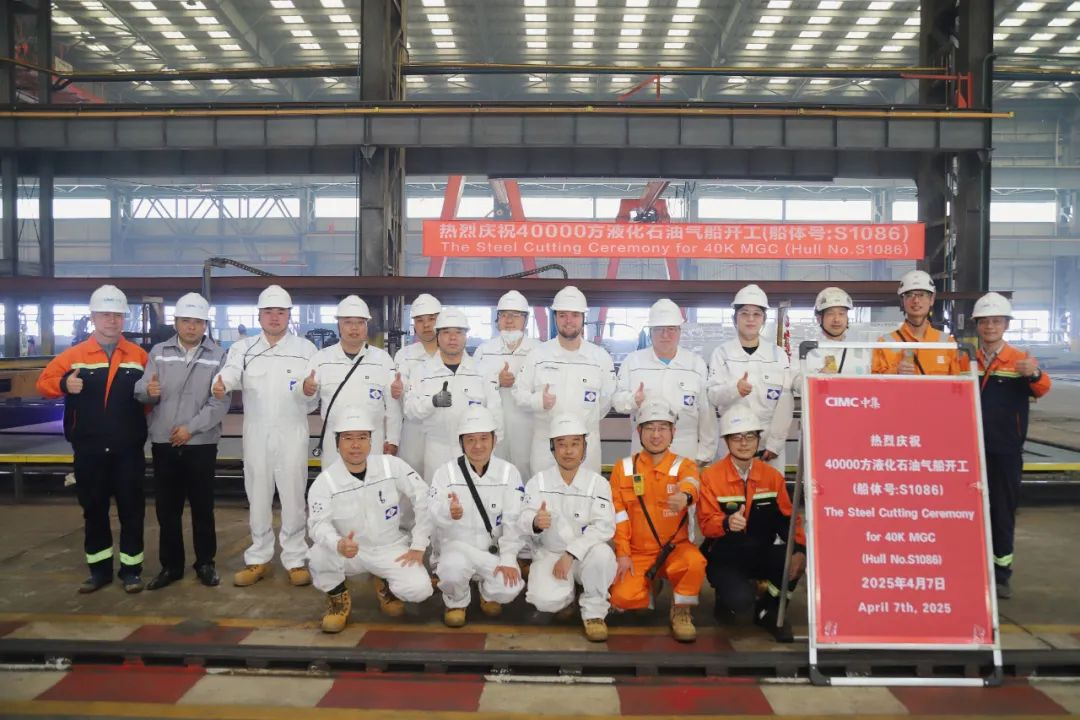

In the morning of that day, a steel cutting ceremony was held for the fourth vessel (Hull No. S1086) in the series of 40,000 m3 LPG / Liquid Ammonia Carriers being built by CIMC SOE for Avance Gas.

It is understood that the construction of this series of vessels is progressing steadily. The first three vessels were started last year, and the first vessel has been laid keel. The S1086, the fourth vessel in the series, has fully absorbed the experience accumulated during the construction of the first three vessels and continued the previous mature design plan. It is a new generation of MGC carriers.

The vessel is equipped with MAN’s green and environmentally friendly dual-fuel main engine. On the one hand, it provides the vessel a design speed of up to 16 knots to ensure efficient transportation; on the other hand, relying on the high-pressure LPG dual-fuel drive mode, it can significantly reduce pollutant and greenhouse gas emissions throughout the operation, accurately meeting the strict environmental protection requirements of the International Maritime Organization.

This LPG/liquid ammonia carrier is equipped with three IMO Type A cargo holds, which not only maximizes the efficiency of cargo capacity utilization, but also effectively promotes the overall economic efficiency. More importantly, the cargo holds are multi-adaptable and can flexibly carry a variety of liquefied gas cargoes such as LPG, liquid ammonia, and vinyl chloride monomer (VCM), fully meeting the complex and ever-changing market transportation demands, greatly enhancing the market competitiveness and adaptability of vessels.

On the same day, CIMC SOE held a groundbreaking ceremony for the third and fourth SPP40 oil platform supply vessels (Hull numbers: S1097 and S1098).

It is understood that the first two vessels of this series of multi-functional oil platform supply vessels have completed keel laying, accumulating valuable experience for subsequent construction.

The two vessels started this time are equipped with two tunnel-type bow thrusters and two fully rotating propellers, coordinated with the oil-electric hybrid power system, which not only gives the vessel extraordinary operational flexibility, but also helps to achieve a double reduction in fuel consumption and emission levels.

These two vessels combine a number of cutting-edge technologies and practical functions, including unmanned cabin, 7-day zero emission, secondary power positioning system, Class 1 external fire-fighting operation, sea surface oil elimination capability, vibration and noise comfort level 3 and other classification notations. In addition, with a deck cargo area of 800 square meters, the vessel can accurately adapt to the transportation needs of various materials such as methanol, fresh water, fuel oil, cement, mud, drilling water and deck cargo, thus expanding the vessel’s multi-functional operational boundaries with high efficiency, and significantly increasing its operational efficiency.