HD Hyundai Heavy Industries recently announced that it has developed the world’s first new 3D printing technology for emergency maintenance, repair and overhaul (MRO) of operating vessels, and recently successfully completed the final evaluation and demonstration of the “3D Printing Fusion Demonstration Technology (3D Printing Digital Workshop)” at HD Hyundai Samho, which is used to “print” maintenance spare parts on operating vessels.

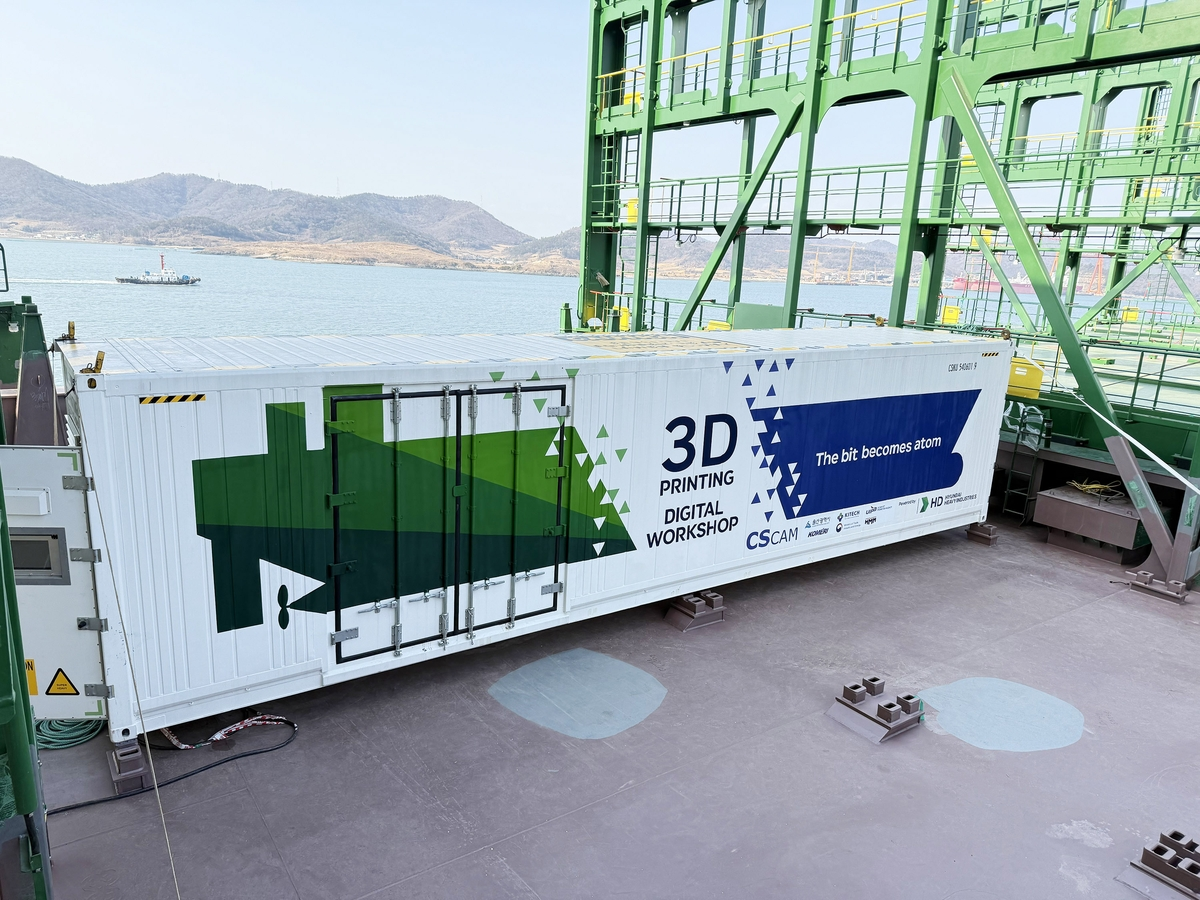

Since July 2023, HD Hyundai Heavy Industries has been working on the “3D Printing Digital Workshop” project as a consortium with the City of Ulsan and its affiliate C-SCAM, HD Korea Shipbuilding & Offshore Engineering (HD KSOE), Hyundai Merchant Marine (HMM), and the Korean Register (KR) with the support of the Ministry of Trade, Industry and Energy of South Korea (MOTIE) of Korea. The project, which is scheduled to be completed by December 2025, is aimed at developing and demonstrating a 3D printing system that can rapidly manufacture maintenance spare parts on its own during operations of a vessel.

Currently, large vessels on long voyages carry a variety of spare parts to cope with emergencies. With the introduction of 3D printing technology, the parts needed for vessels can be manufactured on board at any time and replaced immediately, saving the time and cost of ordering, manufacturing and shipping parts.

During this demonstration, HD Hyundai Heavy Industries not only realized the operation of the 3D printing system on board, but also verified the technology of the vessel motion and vibration reduction device. Vessels sailing on water are in constant motion, so reducing vibration is essential to ensure stable operation of the 3D printing system.

HD Hyundai Heavy Industries said the company plans to officially start the commercialization process of 3D printing technology, in addition to promoting the development of technology for material diversification, such as the joint development of carbon steel powder material for vessels with HD KSOE, a move that is expected to expand the range of 3D printed parts while reducing costs.

HD Hyundai Heavy Industries related personnel said, “This demonstration confirms the competitiveness of 3D printing technology in the shipbuilding industry. We will continue to lead innovation in the field of ship MRO through continuous research and development.”

As early as May 2024, HD Hyundai Heavy Industries became the first shipbuilding company globally to receive the second-stage New Technology Qualification (NTQ) certification from the American Bureau of Shipping (ABS) for its “3D Printing System for Rapid MRO Response in Operating Vessels.”