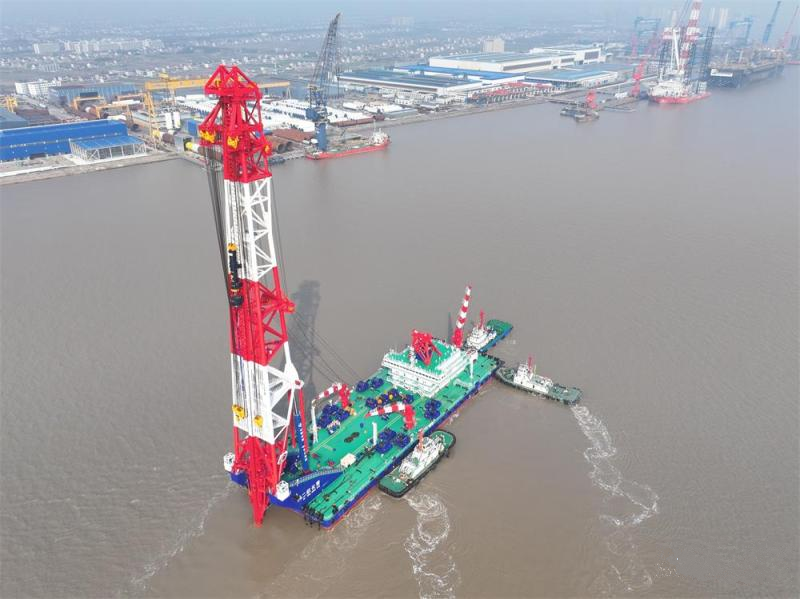

On February 17th, the piling vessel “Erhang Changqing” with the tallest pile frame, largest pile-lifting capacity, longest pile-driving capability, and strongest wind and wave resistance in the world, set sail from Qidong, Nantong. This marks the official commissioning of another “indomitable maritime marvel” in China’s hydraulic engineering construction sector.

“Erhang Changqing” is sailing to the construction site of Hangzhou Bay Cross-Sea Railway Bridge, part of the Suzhou-Jiaxing-Ningbo High-Speed Rail project, and will play a role in the construction of large-scale ports, cross-sea bridges, offshore wind power construction and other engineering construction after put into operation, which will add vitality to the building of super projects and leading technological innovation and intelligent equipment.

“Erhang Changqing”, invested by CCCC Second Harbor Engineering Bureau, was constructed by Shanghai Zhenhua Port Machinery (ZPMC) and commenced the construction on January 18, 2024. It features a high pile frame, large pile-lifting capacity, and strong resistance to wind and waves. With an overall length of 130.5 meters, a beam of 40.8 meters, and a depth of 8.4 meters, the vessel boasts a pile frame height of 150 meters. It is capable of driving piles with a maximum weight of 700 tons and a diameter of 7 meters.

The core equipment of the vessel includes an oil cylinder weighing 385 tons, with a diameter of nearly 2 meters and a total length of 28 meters, making it the largest in the world in terms of weight, diameter, and length. Developed under the leadership of CCCC Second Harbor Engineering Bureau, this achievement represents a breakthrough in domestic production of ultra-large and ultra-long oil cylinders and ensures independent control over core technologies.

At the same time, the vessel is equipped with a DC bus super energy storage system, paired with high-efficiency permanent magnet motors, which significantly reduces energy consumption and carbon emissions. Additionally, it features an advanced pile-driving operation management system and an offshore star station differential pile positioning system. These systems enable automatic calculation and real-time monitoring of pile positioning accuracy, ensuring safe and efficient pile-driving operations.