Economies of scale have mitigated costs for SOVs, raw materials, and wind farm development, but relying solely on large wind farms is not sustainable. Designing smaller SOVs alone is insufficient; a new approach to operations and vessel conceptualisation is essential.

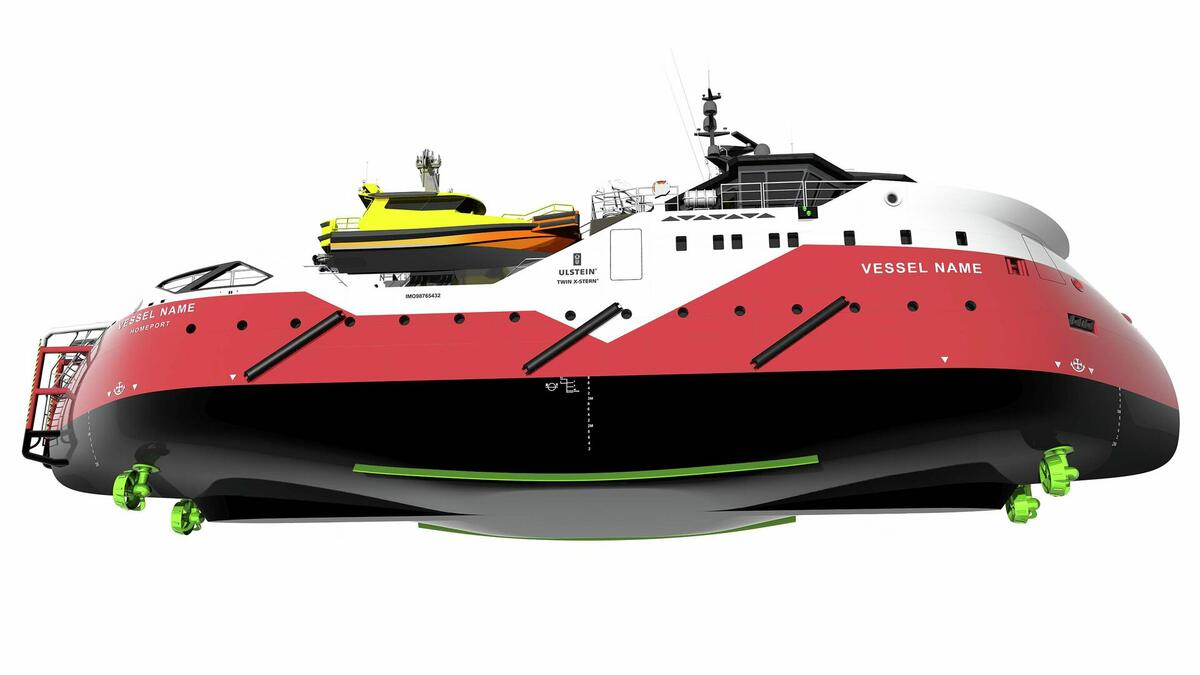

Ulstein’s design team aimed to develop a walk-to-work vessel that reduces vessel CAPEX by at least 50% compared to an SOV, reducing OPEX accordingly, while retaining the majority of the key functionalities and operability. The result is the ULSTEIN SX250.

Ulstein’s design team aimed to develop a walk-to-work vessel that reduces vessel CAPEX by at least 50% compared to an SOV, reducing OPEX accordingly, while retaining the majority of the key functionalities and operability. The result is the ULSTEIN SX250.

The ULSTEIN SX250 transforms offshore wind farm servicing by bridging the gap between CTVs and SOVs, introducing new service logistics. One or more SX250 vessels can support a full-sized SOV, the latter handling larger tasks while two to three SX250 vessels manage the smaller jobs. This setup meets service requirements and maintains the necessary up-time and it allows for more detailed operational planning and distribution of workload.

The ULSTEIN SX250 design is best suited as the preferred solution for small and medium-sized windfarms, windfarms located in areas with benign and moderate sea states, or in shallow waters. ULSTEIN SX250 is also a perfect supplement to cater for the additional maintenance activities typically carried out during the summer campaigns.

The ULSTEIN SX250 is based on the proven TWIN X-STERN solution, which ensures high operability and excellent seakeeping capabilities. It measures 47 meters in length and 12.5 meters in width, accommodating between 32 to 40 individuals on board (POB). The vessel has a maximum speed of 10 knots and can operate in conditions of up to 2 meters significant wave height (Hs).

Safety is a major focus, with people and goods transferred via a basket in an Offshore Passenger Transfer System (OPTS), Bring-to-Work System, or conventional gangway.

The vessel can be customised with different arrangements and topside equipment, allowing it to adapt to various operational needs and making it easy to repurpose for new tasks. The vessel concept design relies on existing off-the-shelf hardware and technologies to ensure effective W2W operations while reducing CAPEX and OPEX.

Depending on operational needs, various setups can include a gangway system for personnel/goods, a daughter craft, a deck storage container, a work or observation ROV, or a fast rescue craft/workboat.

The ULSTEIN SX250 is designed to meet the needs of the offshore wind service industry, offering a cost-effective and versatile solution. It is also more environmentally friendly, significantly reducing material consumption during the shipbuilding phase compared to a Service Operation Vessel (SOV). Additionally, it lowers fuel consumption during operations. Its reduced energy consumption facilitates the transition to zero-emission operations by enabling the integration of alternative fuels.

By reducing its environmental footprint, the ULSTEIN SX250 aligns with the industry’s push towards more sustainable