Chinese shipbuilder Jiangxi New Jiangzhou Shipbuilding Heavy Industry Co., Ltd. (New Jiangzhou Shipbuilding Heavy Industry) has recently received new orders for high-end chemical tankers and gas carriers one after another.

Singapore’s MAC Shipping has revealed that it has ordered four duplex stainless steel chemical tankers from Xin Jiangzhou Shipbuilding Heavy Industry, which are expected to be delivered from 2026 onwards, marking the owner’s first newbuilding project.

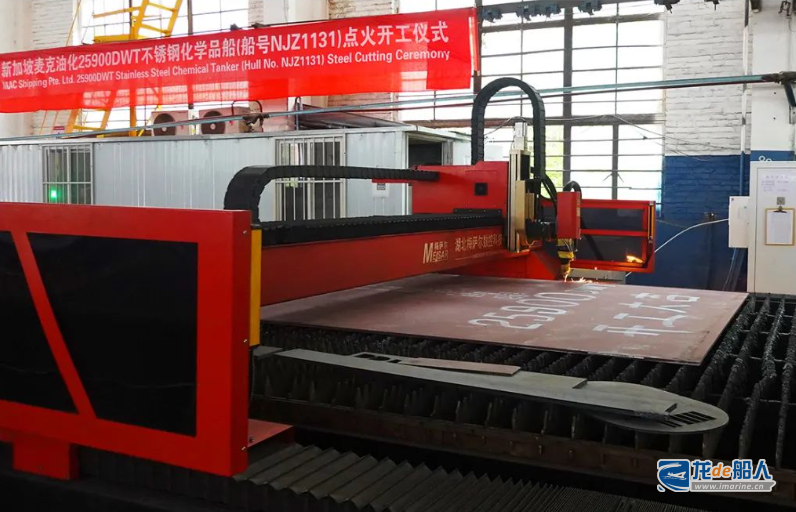

On October 21, 2024, New Jiangzhou Shipbuilding Heavy Industry cut steel for the first 25900DWT duplex stainless steel chemical tanker, built for MAC SHIPPING. The vessel is built with LOA of 158.98m, width of 27m, design draft of 9.5 m, speed of 14 knots, and is driven by a low-speed diesel engine with a power of 5CKW and a FPP system.

The vessel is designed and built strictly in accordance with the specifications of ABS, and with double hull, double bottom, one complete continuous freeboard deck and forecastle, poop with accommodation deckhouse, transom stern with one hanged rudder as well as bulbous bow. The vessel has been designed with environmental protection and energy saving in mind and is equipped with advanced energy saving devices to meet the requirements of EEDI (Energy Efficiency Design Index) Stage 3. The vessel is suitable for the carriage of kinds of IMO II & III chemicals and Annex I oil cargos, with a maximum cargo density of 2.0t/m³, fully meeting the needs of Singapore MAC Shipping Pte LTD for a diversified, efficient and safe vessel.

The 25,900 tons ocean-going duplex stainless steel chemical tanker is the largest high-end stainless steel chemical tanker project undertaken by Jiangxi Province. Its smooth steel cutting marks the new Jiangzhou Shipbuilding Industry officially entered the field of high-end chemical tanker construction.

Founded in 2021, MAC Shipping initially operated bulk carriers and subsequently expanded its operations, shifting its focus to chemical tankers in 2022.

It is worth noting that, on October 31, 2024, Jiangxi New Jiangzhou Shipbuilding Heavy Industry Co., Ltd. and Shenzhen Haihong Shipping Co., Ltd. signed a contract for the construction of a 7,000 m3 LEG (ethylene) carrier in Ruichang City. This signing marks the New Jiangzhou Shipbuilding Heavy Industry’s high-end vessel construction strategy to improve the quality, officially entered into the field of gas carrier construction.

The vessel is the world’s first domestically designed and manufactured semi-cooled semi-pressurized LEG carrier. Suitable for loading: ethylene, ethane, propylene, propane, commercial propane, butane, propane/butane mixture, butene, anhydrous ammonia, vinyl chloride monomer (VCM), butadiene, diethyl ether, isoprene (monomer), isopropylamine, ethylamine, vinyl ether, etc. The vessel is designed by MARIC, steel single deck (freeboard deck), with forecastle and poop decks. The Engine Room, accommodation and wheelhouse are arranged at the aft. The cargo hold area is equipped with two independent single cylinder C-type tanks of 3500 m3 each and equipped with loading and unloading equipment, which can carry one type of goods or two types of goods at the same time.

The vessel has an invisible bulbous bow (VS-BOW) and uses a post-paddle energy saving device “CAPRO”. The vessel flew the Chinese flag, entered the China Classification Society, and was built according to the Specifications of the China Classification Society. The total length of the vessel is 115 meters, the width is 19 meters, the depth is 10.4 meters, the design draft is 6.1 meters, the structure draft is 6.6 meters, the load capacity is up to 6200 tons, the use of single diesel engine, single shaft and single propeller design, the speed is 14.5 knots. Suitable for international unrestricted navigation.