German engine manufacturer MAN Energy Solutions has filed an impressive 37 patent applications during the development of its ammonia-powered marine engines. Currently, the company has completed 71,000 R&D man hours, equivalent to 48 R&D man years.

Investigating the combustibility for its two-stroke ammonia-powered engines begin in 2019, while hazard identification and hazard operations studies begin in 2020. The program was initiated in 2020 when its 4T50ME-X test engine became the platform for ammonia engine development. This was followed by a HAZID workshop on the engine concept and the first evaluation of the combustion chamber.

In 2021, the company finalized the basic concept of the engine and ammonia fuel supply system. MAN Energy Solutions was granted six patents, two in 2020 and four in 2022, with 3 iadditional filed during this period. 15 additional patents applications were completed in 2022, 9 more in 2023 and 4 more are expected to be completed in the near future.

The applications extend beyond the engine itself to include safety systems that are critical to ammonia operations. Nikolaos Kourtidis, MAN Energy Solutions’ two-stroke promotion and customer support representative, said: “We have already been granted six patents and will continue to invest in this area.” The idea is that by the end of 2024 we will have a well-designed, safe and reliable product that is consistent with the reputation of our MAN brand.”

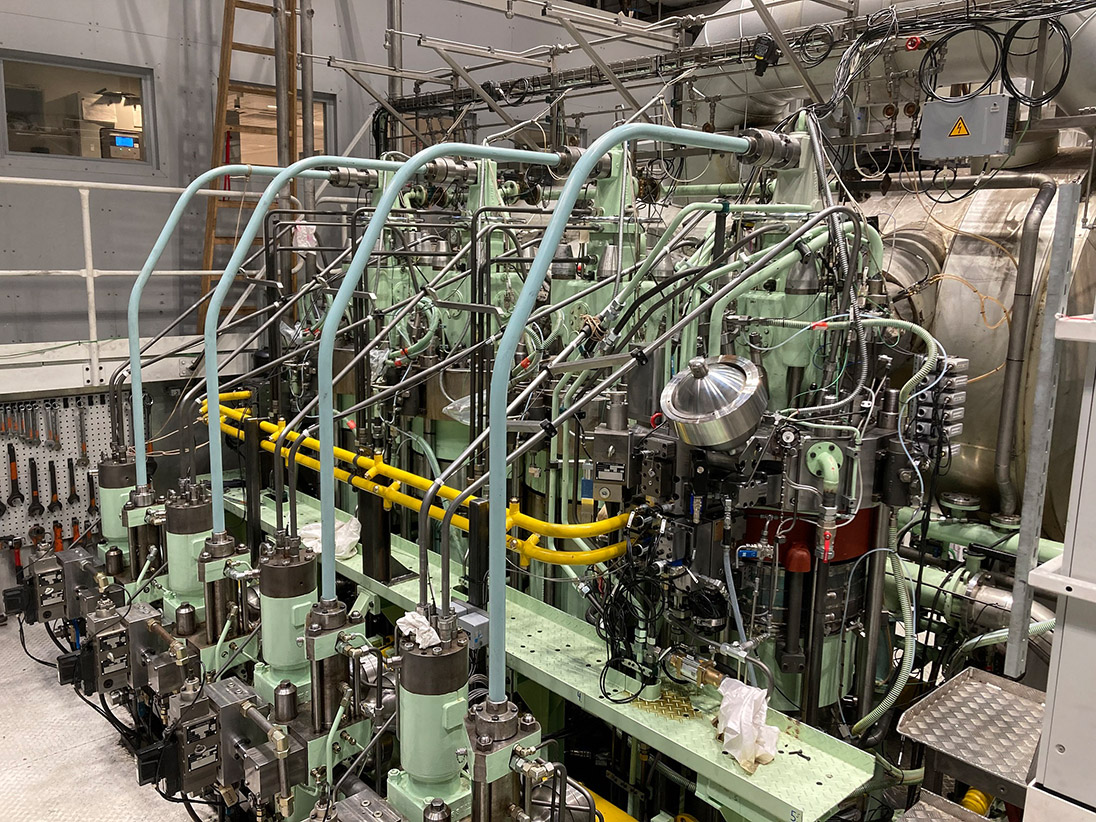

In July 2023, the Company completed combustion testing of the two-stroke ammonia engine at its research center in Copenhagen, followed by successful 100% load operation of the ammonia engine in August. Further tests are planned for 2023 and 2024, in parallel with the design and testing of the commercial version of the ammonia engine. Engine delivery is scheduled for 2024, when the world’s first ammonia-fueled engine will be delivered to a shipyard.

The engine itself is based on the Low Grade Ignition (LGI) combustion principle, similar to the methanol engines from MAN Energy Solutions. Although the components are designed for ammonia operation, a diesel cycle is utilized. During compression, air is compressed in the cylinder and a small pilot fuel is ignited. This ignition source is used to release the ammonia, with initial pilot tests ranging from 10% to 15% and a development goal of 5%.

Innovation is not just limited to the engine itself. MAN Energy Solutions has invested heavily in peripheral systems, including ammonia card systems, fuel filling facilities with sprinkler systems, ammonia fuel filling stations, service tanks, and double-walled ventilated absorbers that act as mini-scrubbers at the outlet.