Recently, the Second Barrier Tightness Test (SBTT) of the containment system developed by Jiangnan Shipyard, a subsidiary of China State Shipbuilding Corporation (CSSC), successfully passed the acceptance of the shipowner, classification society and GTT, marking the successful construction and testing of the containment system.

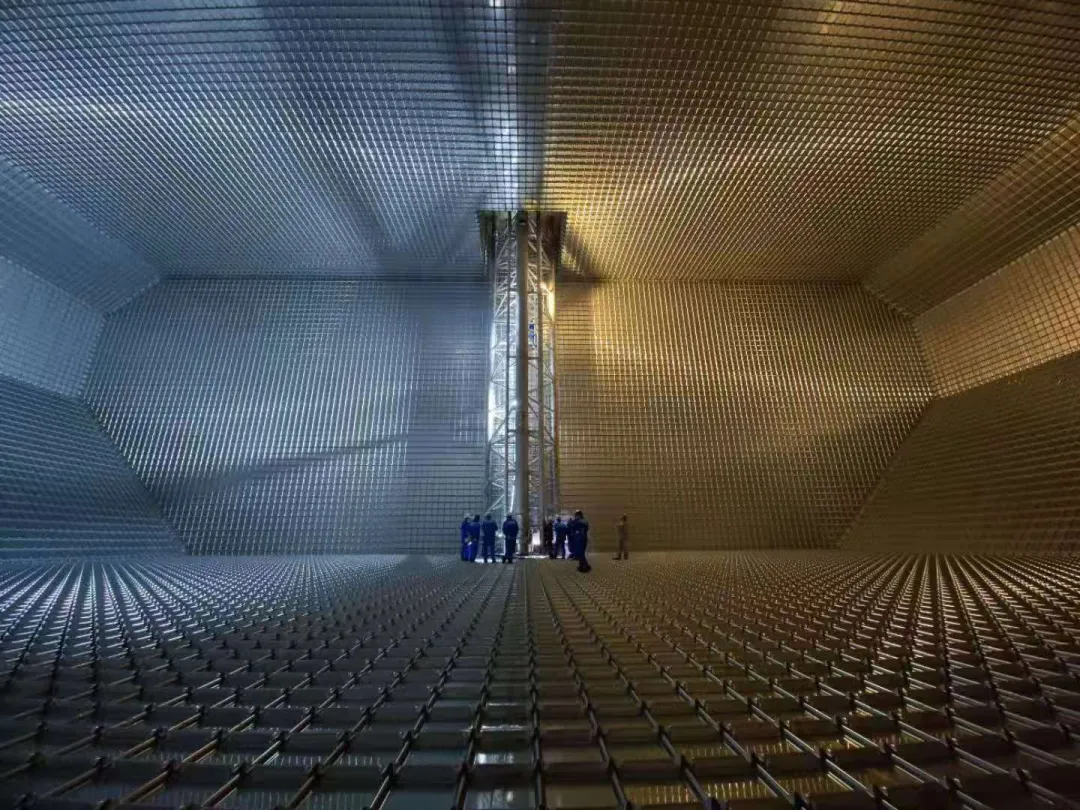

Focusing on the characteristics of the Mark III Flex containment system, Jiangnan Shipyard project team identified major technical, quality, cycle and safety risks, sorted out more than ten topics and carried out special research. The research results support high-quality and high-efficiency construction on site.

Mr.Philippe BROSSEAU, CCS Supervisor, Owner’s Site Supervision Team said, “I am officially satisfied with these SBTT results on our first LNGC 175k, the values are homogeneous and can be considered as excellent. This success is the result of the excellent technical relation between ADNOC CCS team and JN Management and CCS department.”

Mr. Vincent Guenoden, Resident Surveyor of DNV, said, “We are glad to be part of this successful results, and we believe that the team effort and teamwork of Jiangnan shipyard together with experience exchange, technical discussion, and daily surveys of DNV/GTT & ADNOC site representatives had been the key for this great achievement.”

Mr. Sebastien FATET, GTT Site Manager in Jiangnan Shipyard added, “It’s an excellent result, it concluded successfully this first 175k mark3 LNG carrier in Jiangnan. ”

It is reported that in order to further improve the quality and efficiency of the containment system, Jiangnan Shipyard has carried out a number of research projects, including intelligent containment construction information platform, automatic installation robots, new containment construction platform, pump/tower/cover integration, etc.