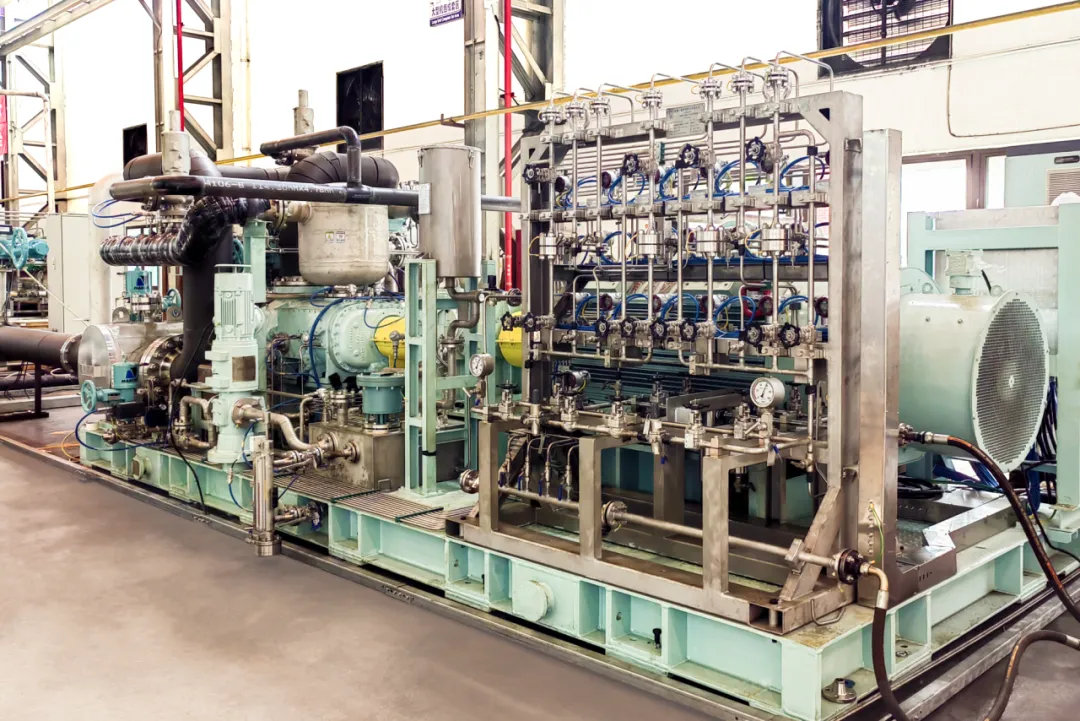

Recently, the BOG screw compressor for 174,000 cbm LNG carrier, which was independently developed by Shanghai Marine Diesel Engine Research institute (SMDERI), has completed installation and passed the factory acceptance test (FAT), realizing the development of the first large-scale BOG screw compressor prototype for LNG carrier in China.

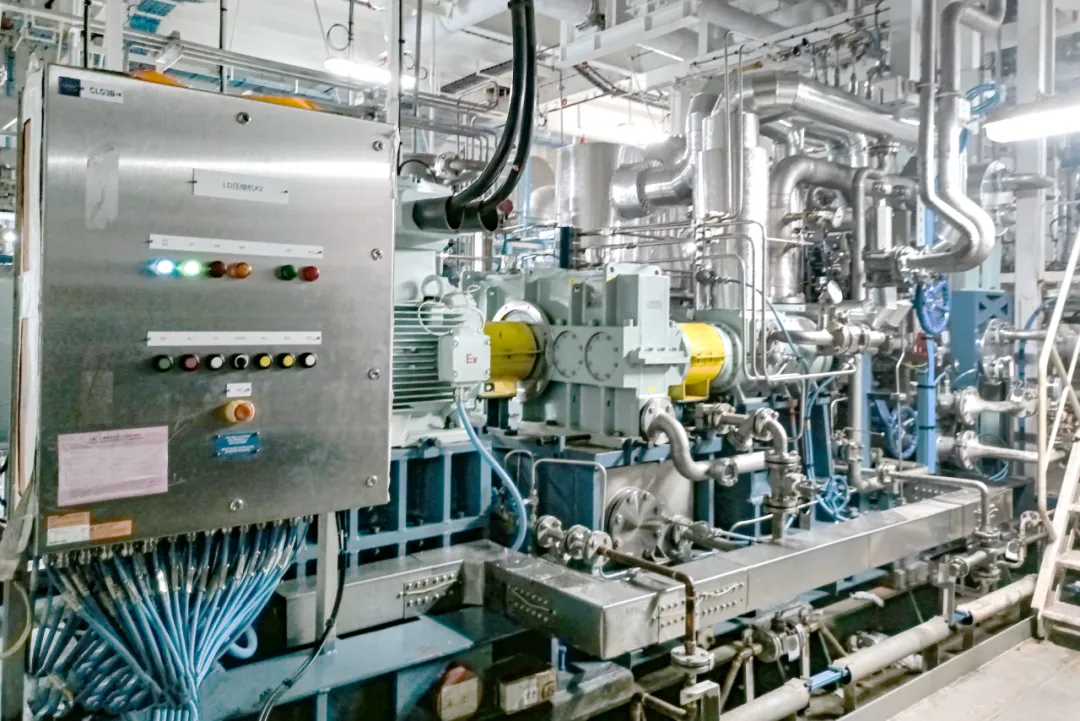

As early as July this year, SMDERI has successfully delivered two sets of small and medium-sized BOG screw compressors for the dual-fuel main engine gas supply of the “Huaihe Nengyuan Qihang”, the world’s first and China’s first river-sea direct 14,000 cbm liquefied natural gas (LNG) LNG bunkering vessel built by Hudong-Zhonghua Shipbuilding.

In this project, SMDERI’s BOG screw compressor has excellent vibration and sealing performance, and has a fully automatic control function, which can meet the bunkering vessel’s stable gas supply needs at various sailing speeds, and has successfully cooperated in the implementation of multiple bunkering operations.

This BOG screw compressor for 174,000 cbm LNG carriers developed this time not only continues to use the sealing and vibration control technology that has been proven effective on “Huaihe Nengyuan Qihang”, but also has a larger gas processing capacity and can adapt to a wider BOG processing range. The overall layout of the machine is more compact and easy to operate.

This product indicates that SMDERI has the ability to design and supply a full range of small, medium and large BOG screw compressors for LNG carriers, providing strong support for improving the localization of China’s LNG carrier equipment and promoting the development of China’s LNG industry chain.