On the first day of SMM trade fair in Hamburg, China Classification Society (CCS) released many ship types adopting the green and low-carbon new technologies through collaboration with the industry, especially including new fuel ships of methanol, ammonia, liquefied natural gas (LNG) and ammonia carriers, ammonia bunkering vessels, etc. During the development of these ship types, CCS has deeply involved in the research on the technical solutions, general layout, structural optimization, etc. for ships, and provided comprehensive technical support for compliance with the technical specifications and regulations for ships.

- Marine Design & Research Institute of China (MARIC) – ship type approval of 20,000m3 ammonia bunkering vessel and 16,000 TEU ammonia container ship

With advanced environmental protection features and efficient cargo handling capabilities, the 20,000m3 ammonia bunkering vessel is used for ammonia fuel bunkering operations in major ports around the world. The ship is equipped with ammonia leak detection system, ammonia capture system, NOx and N2O catalytic reduction system, etc. The ship adopts a breakthrough design of two single cylinder C-type cargo tanks for a lower cargo boil-off rate (BOR) and a higher utilization rate of cabin capacity. It is equipped with three collection areas and two kunckle cranes to match the receiving vessel of different scales on a larger scale, and improve the matching capability of bunkering.

The 16,000 TEU ammonia container ship is a large ammonia-fueled container ship. By taking ammonia as marine fuel and combined with exhaust gas treatment, the ship can significantly reduce sulfur oxides and nitrogen oxides, and achieve zero carbon dioxide emissions. The ship is equipped with independent B-type ammonia tank ensure sufficient endurance and efficient cargo carrying capacity through optimized layout. Its endurance mileage can support single trips on the Asia-Europe route and other mainstream routes. At the same time, the ship is equipped with a high-efficiency energy-saving device and advanced navigation equipment, which is suitable for dual-mode operation of diesel and ammonia, with excellent energy consumption indicators.

- Shanghai Merchant Ship Design & Research Institute (SDARI) -16,500TEU LNG dual-fuel container ship

The 16500TEU LNG dual-fuel container ship was designed by SDARI, which has a LNG storage tank capacity of about 11,000m3, efficient cargo loading capacity, advanced environmental protection features, EEDI Phase III energy efficiency standards, and is equipped with a modern ship operation support system.

The main engine of this ship is equipped with iCER energy-saving system, and the auxiliary generator is equipped with SCR system to meet the Tier III nitrogen oxide emission requirements. The main engine, auxiliary generator set, and auxiliary boiler of this ship are equipped with a dual fuel supply system for combustion of low sulfur fuel and LNG gas fuel to meet the requirements for sulfur oxide emissions.

- China Ship Design & Research Center Co., Ltd. (CSDC) -18,000m3 ammonia bunkering vessel

The cargo tank of this 18,000 m3 ammonia bunkering vessel adopts a semi-pressurised and semi-refrigerated design, and the most significant feature of the ammonia bunkering arm design is the use of an emergency release system, which can immediately disconnect the connection between the ammonia-fueled ship and the ammonia bunkering vessel in case of emergency.

At the same time, this ship is equipped with dual POD type thruster and an efficient electric propulsion system, which has flexible maneuverability and is suitable for ammonia supply services worldwide. It has advanced environmental characteristics and a safety system that meets the requirements of the International Maritime Organization (IMO).

- CSSC Huangpu Wenchong Shipbuilding Company Limited -3500TEU ammonia-fueled container ship

This ship was designed by CSSC Huangpu Wenchong Shipbuilding Company Limited. Research has been conducted on the layout of relevant cabins and the design of fuel system when ammonia system is used on the existing ship types, including risk identification and assessment of ship safety and fuel toxicity. Through ship type optimization, this ship has efficient container loading capacity, and superior energy consumption indicators, cargo carrying capacity, adaptability, etc.

In the afternoon of the exhibition, the ship type approval and release activity has continued.

CCS, together with China’s leading LNG shipbuilding enterprise Hudong-Zhonghua Shipbuilding (Group) Co., Ltd., launched four new types of LNG cargo and fuel carriers and bunkering vessels. CCS Vice President Zhao Yan issued the ship type approval certificate for the following ship types to Vice General Manager Song Wei of Hudong-Zhonghua Shipbuilding (Group) Co., Ltd.

150,000m3 ULEC

This ship adopts an innovative three cargo hold design scheme with MARKIII type enclosure system, with the boil-off rate (BOR) as low as 0.08%/day and a maximum unloading rate of 5100m3/h. It can dock at Morgan’s Point and Netherland in the United States. The main engine of this ship adopts ethane dual fuel, and is equipped with a SCR device to meet the IMO Tire III emission requirements. It is characterized by light structural weight, strong cargo carrying capacity, and excellent comprehensive performance, as well as being green, environmental-friendly, safe and reliable, thereby providing a highly competitive new option for the shipping industry.

88,000m3 ammonia carrier

This liquid ammonia carrier adopts an independent A-type liquid cargo enclosure system scheme, and the power system adopts a dual fuel low-speed engine of fuel/liquid ammonia and a conventional fuel generator, which meets the IMO Tire III emission requirements. It is specially designed for ammonia leak detection, transportation pipeline and supply system, and water spray absorption system, and escaped ammonia can be collected even in the event of power outage on the entire ship, effectively avoiding the risk of toxic ammonia injury to crew members during operation.

40,000m3 liquefied CO2 carrier

This ship adopts ammonia power in an innovative manner while achieving liquefied CO2 transportation. The liquid cargo system adopts an innovative low-pressure solution, and is compatible with liquefied petroleum gas transportation. The ship type design has provided two cabin pressure control schemes of CO2 re-liquefaction and liquid cargo tank pressure storage to reduce CO2 evaporation rate. The power system adopts a dual-fuel engine of fuel/liquid ammonia, and is equipped with iCER system to meet the IMO Tire III emission requirements. At the same time, the superstructure bow layout design is specially adopted to provide a reserved plan for the future installation of carbon capture system.

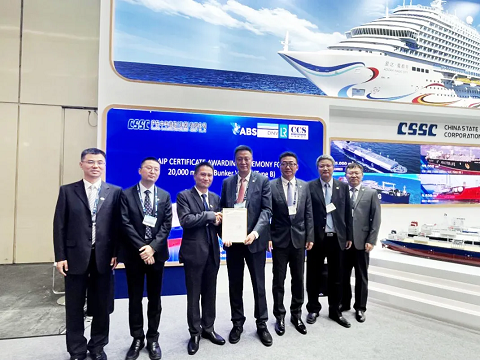

20,000m3 B-type independent cabin LNG bunkering vessel

Based on the world’s first B-type independent cabin 14,000m3 LNG bunkering carrier delivered in August 2024, Hudong-Zhonghua Shipbuilding (Group) Co., Ltd. has further successfully and independently developed the world’s largest 20,000m3 LNG bunkering carrier through the iterative update of ship type. This ship adopts the B-type LNG enclosure system with independent intellectual property rights of Hudong-Zhonghua Shipbuilding (Group) Co., Ltd., with a boil-off rate (BOR) as low as 0.21%/day. It is equipped with a re-liquefaction device to achieve complete re-liquefaction and green low-carbon emission of evaporated gas. In terms of propulsion power, it adopts a dual-fuel electric propulsion + full rotary propulsion system to achieve full-gas mode operation under various working conditions, which meets the IMO Tire III emission requirements. At the same time, the “door-to-door delivery” autonomous berthing of various LNG receiving ships can be achieved.