On August 26, Jiangnan Shipbuilding, a subsidiary of China State Shipbuilding Corporation (CSSC), signed a contract with Eastern Pacific Shipping Pte. Ltd. (EPS) for the construction of six 150,000 m3 Ultra Large Ethane Carriers (ULEC).

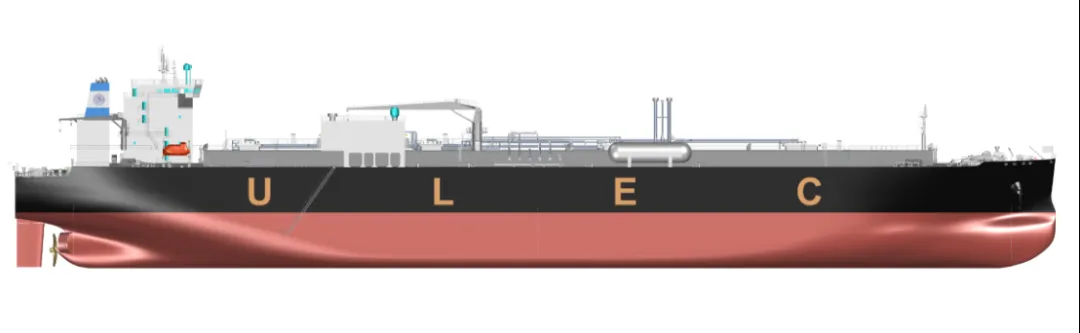

The above contracted ethane carriers are the latest generation of ULECs independently developed by Jiangnan Shipbuilding. The cargo containment system adopts the Mark III membrane containment system of France’s GTT Company. And ULEC is named after the Louisiana state flower “MAGNOLIA”.

The ULEC is designed to maximize the use of U.S. ethane terminal waters to maximize cargo capacity. Classed by American Bureau of Shipping (ABS), the ethane carrier is equipped with a cargo containment system capable of loading of ethane, ethylene and liquefied petroleum gas (LPG). Its LNG-ready capability provides maximum cargo loading flexibility and adaptability throughout the ship’s life cycle.

The ULEC has fully considered the typical route characteristics of the trans-Pacific and trans-Atlantic routes and the operating characteristics of ethane transportation, fully optimized the liquid tanks and hull lines by means of computer fluid dynamics (CFD) and ship model trials, so as to make its hydrodynamic performance reach the optimal overall and completed the tank design of Mark III containment system and the optimal layout of the insulation board.

The development and design of this ULEC also draws on Jiangnan Shipbuilding’s experience in building cargo systems for very large ethane carriers (VLECs) and membrane containment systems for LNG carriers, which are adapted and optimized according to the output and receiving terminals.

In addition, the ULEC is equipped with a powertrain combination of an ethane dual-fuel main engine, desulfurization tower, selective catalytic reduction (SCR) system, and a shaft generator, which balances the economics of ethane and fuel oil. MAGNOLIA is a Furture-Proofing, redefining the preferred vessel for long-distance ethane transportation.

EPS is a renowned company with a 60-year outstanding history in the shipping industry and is one of the largest independent shipowners in the world. Headquartered in Singapore, EPS manages a diversified fleet of more than 270 vessels, including: bulk carriers, containerships, car carriers, tankers, petrochemical carriers, LPG carriers, LNG carriers, with a total deadweight tonnage of 28 million tons and an average age of less than 10 years, of which more than 80 are dual-fuel vessels. In addition, EPS has placed orders for more than 100 new vessels to be delivered and put into operation over the next five years.

In 2023, EPS partnered with Jiangnan Shipbuilding for the first time to order six of the world’s largest Very Large Ammonia Carriers (VLACs). The VLACs are of “Ammonia Ready” and have been praised by the shipping industry as “the world’s greenest vessel”.

This time, EPS and Jiangnan Shipbuilding join hands again to build the world’s largest capacity Mark III thin-film ethane carrier, which not only expands the cooperation between Jiangnan Shipbuilding and GTT, but also provides more competitive ethane freight rates and flexible cargo combinations for charterers.

As a leading shipbuilder in China’s for LNG carrier design and construction, Jiangnan Shipbuilding is committed to the process innovation of large-scale membrane LNG carrier construction methods and further expanding these advanced methods into the construction of ULECs, which will deliver this batch of 6 ULECs with high quality and on schedule.