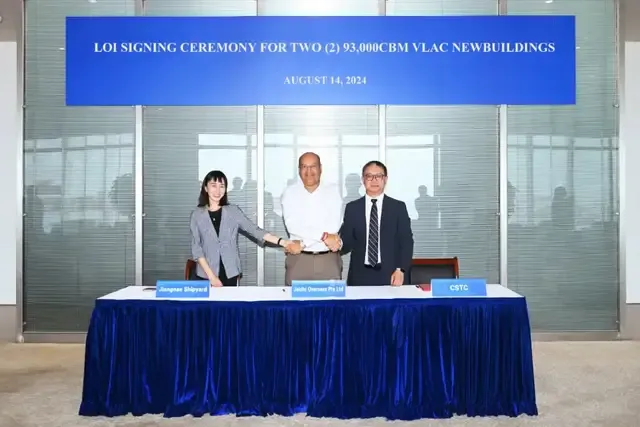

On August 14th, Jiangnan Shipbuilding, a subsidiary of China State Shipbuilding Corporation (CSSC), and China Shipbuilding Trading (CSTC) jointly held a signing ceremony for the construction contract of two 93,000m3 Very Large Ammonia Carriers (VLAC) with JALDHI OVERSEAS PTE LTD (hereinafter referred to as “JALDHI”). Also, the two parties signed a letter of intent (LOI) for the re-building project of two 93K VLACs.

The order for 2+2 VLAC is another order signed after Jiangnan Shipbuilding signed a contract with AW Shipping jointly with CSTC on July 23rd.

This cooperation is the first time for JALDHI to build large gas carriers in China and the first time for JALDHI to place an order with a shipyard under CSSC.JALDHI is a Singapore-based shipping company established in 2004, specializing in chartering and operating around 400 vessels per year. In addition to serving Bothra Group, its fleet is also used for its own cargo trading, and JALDHI also owns shares in LPG and LNG terminals in India. With the successful signing of this project, JALDHI and Jiangnan Shipbuilding have joined hands to bring new impetus to the global green decarbonization business in the future.

The 93,000m3 VLAC is a derivative of the fourth-generation VLGC (Panda 93A) independently researched and designed by Jiangnan Shipbuilding, which is the world’s largest liquid ammonia carrier at present, and is not only the first choice for long-distance transportation of green ammonia, but also can be fully loaded with liquefied petroleum gases, such as propane, butane and other liquefied petroleum gases.

The VLAC has an overall length of 230.0 meters, a beam of 36.6 meters and a depth of 22.5 meters. It adopts a new generation of low resistance line shape developed completely independently, which enables it to have excellent and balanced performance under full load, ballast and different specific gravity liquid cargo loading conditions.

The engine room of this VLAC is equipped with a mature LPG dual-fuel main engine and shaft generator to meet the current carbon emission requirements. Meanwhile, for the ammonia-fueled main engine under research and development, Jiangnan Shipbuilding is also actively working closely with the main engine manufacturer and fuel supply system manufacturer on the treatment of nitrous oxide, etc., to lay a foundation for the application of ammonia-powered main engine in the later stage.