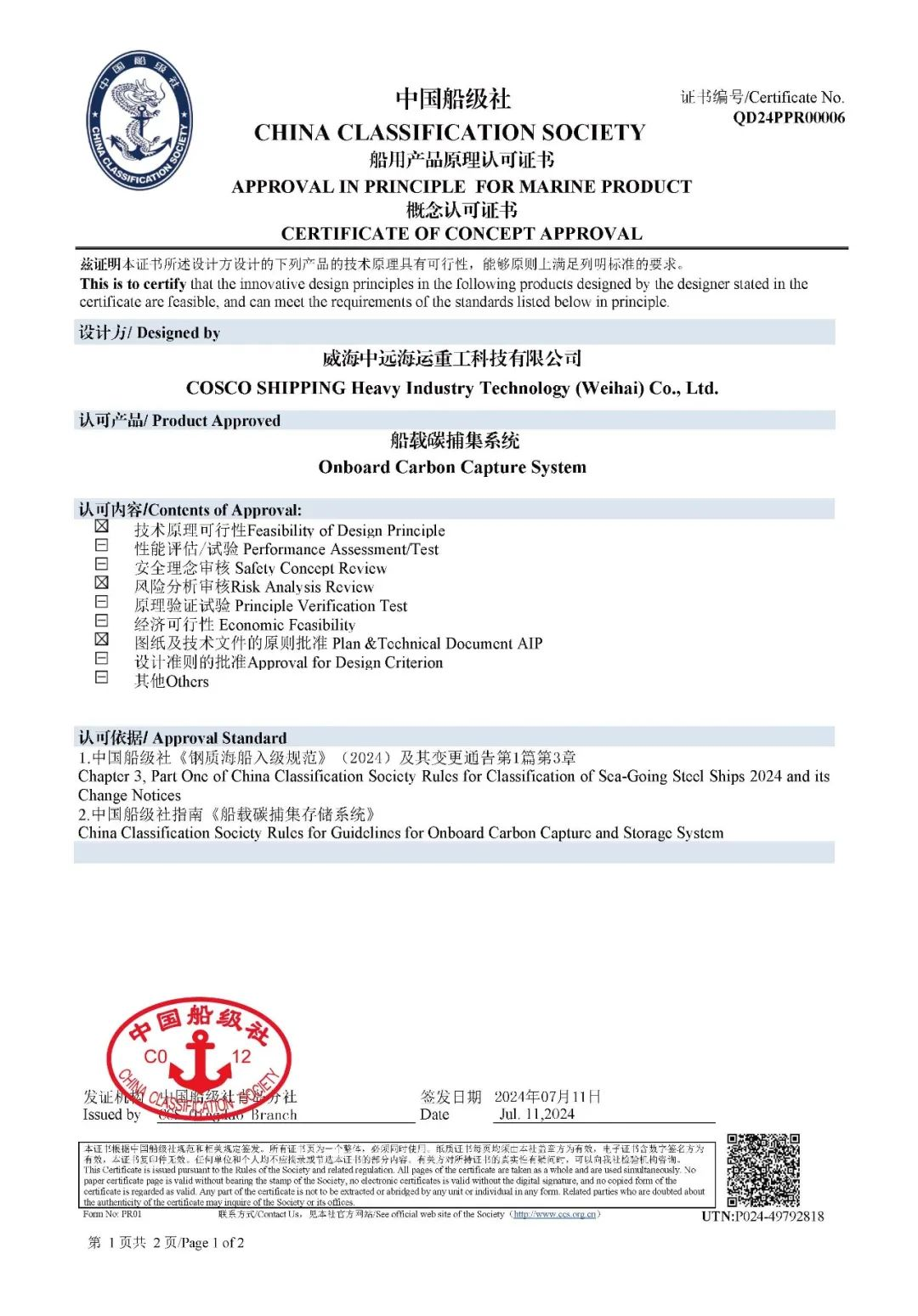

Recently, the onboard spray carbon capture system independently developed by Nantong COSCO Ship Equipment/ COSCO SHIPPING Heavy Industry Technology (Weihai) (“CHIT”) has successfully obtained the Approval-in-Principle (AIP) certificate issued by China Classification Society (CCS), which is another major technological breakthrough following the onboard super gravity carbon capture system.

The spray carbon capture system is based on the core of spray tower technology, using nozzles to transform the absorbent into a mist or water column spraying jet to cover a large area, where the gas and liquid come into full contact, realizing gas-liquid mass transfer.

Compared with super gravity carbon capture technology, spray carbon capture technology has the advantages of high maturity, large space for energy-saving transformation, and simple structure and easy maintenance of tower equipment.This system is suitable for all types of ships, especially for flue gas treatment of large-displacement ships, and can improve the efficiency of carbon dioxide absorption and energy utilization by using comprehensive energy-saving technologies such as midrange cooling, MVR, and waste heat utilization to improve carbon dioxide absorption efficiency and energy utilization, and effectively reduce system energy consumption and maintenance costs.

Shower tower technology can take advantage of its own technical advantages and integrate with the super gravity technology to customize the technical route according to customer needs, forming a set of highly efficient and compact onboard carbon capture system, providing an all-round solution to carbon capture technical problems.

The development of spray carbon capture technology has further improved the applicability of the onboard carbon capture system to various ships, and provided strong technical support for the establishment of a sound system of onboard carbon capture equipment and the enhancement of market competitiveness.