According to China State Shipbuilding Corporation (CSSC) Huangpu Wenchong Shipbuilding news, in the first half of the year, the ship and marine business of Huangpu Wenchong fulfill the delivery of 13 ships, orders over 10 billion, the number of handheld orders for feeder container ships ranked first in the world, and the annual orders are expected to exceed the mark of 20 billion.

In terms of production, in the first half of the year, Huangpu Wenchong completed a total of 85 ship production nodes, including the delivery of 13 ships, exceeding the progress target to complete the delivery of 2 ships.

Among them, 3,000TEU container ship series realized batch production, and 3 units in this series were delivered in the first half of the year, with an average of 4 months ahead of the contract period. By optimizing the construction process to shorten the period of hatch cover installation and test box, the first 32,000DWT heavy lift vessel was delivered 65 days ahead of the contract period despite the delay in the arrival of the hatch cover

In terms of receiving order, Huangpu Wenchong insisted on focusing on the main ship types, in the first half of 2024 it has undertaken orders for 9 types of 33 new ships.

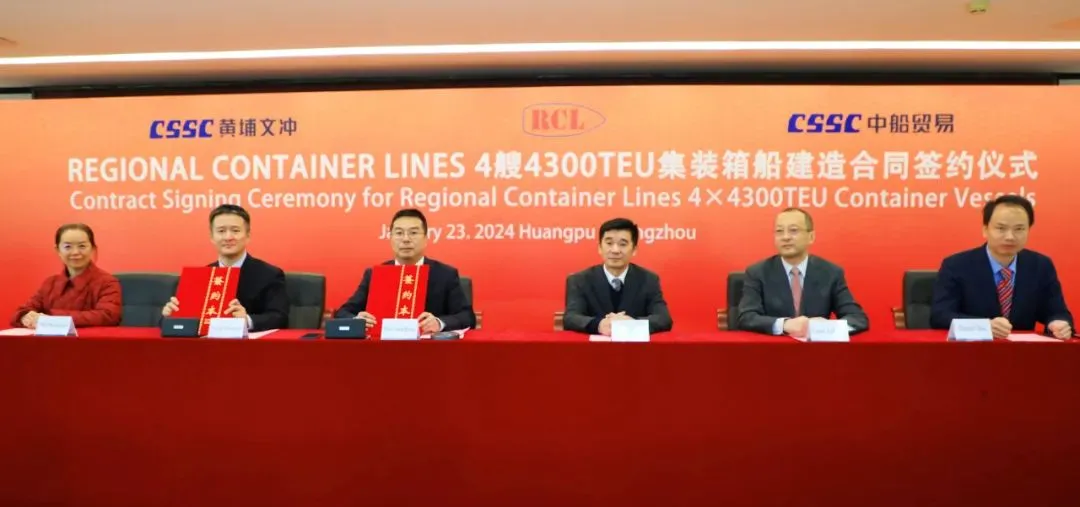

Among them, Huangpu Wenchong signed orders for 4300TEU container ships with Thailand and Turkey shipowners for a total of 12 units, realizing the breakthrough from feeder container ship field to medium-sized container ships. The self-designed 2400TEU methanol dual-fuel container ship won the batch order for the first time, successfully opening the breakthrough of new energy ship market. Also the company received orders for two types of ammonia dual-fuel LPG/liquid ammonia carriers of ammonia dual-fuel LPG/liquid ammonia carriers of 25,000 m³ and 41,000 m³, which provide support for Huangpu Wenchong to build the gas carriers into new fist products.

In addition, Huangpu Wenchong continued to push forward the digital transformation, completed the on-line application of the core production planning module in the integrated production management information platform, and carried out the optimization of the operation of the platform’s various functional modules, carried out the development of the hull/tube/coating MES and the application of the cell phone APP dispatching, etc., and realized the smooth and efficient operation of the platform.

In the second half of the year, Huangpu Wenchong will take lean management as the starting point to realize balanced production, on-time production and safe production, and improve efficiency indexes while steadily increasing production volume, so as to strive to realize the blueprint of high-quality leapfrog development.